Coalbed methane

[citation needed] Unlike much natural gas from conventional reservoirs, coalbed methane contains very little heavier hydrocarbons such as propane or butane, and no natural-gas condensate.

Some coal beds have long been known to be "gassy," and as a safety measure, boreholes were drilled into the seams from the surface, and the methane allowed to vent before mining.

The US Department of Energy funded research into a number of unconventional gas sources, including coalbed methane.

Coal displays a stress-sensitive permeability and this process plays an important role during stimulation and production operations[8][citation needed].

This unique behavior is because of shrinking of coal, when methane is released from its matrix, which results in opening up of fractures and increased permeability.

Such a failure has been attributed to sudden decrease in the fracture permeability of the reservoir[11][9] The thickness of the formation may not be directly proportional to the volume of gas produced in some areas.

[citation needed] The pressure difference between the well block and the sand face should be as high as possible as is the case with any producing reservoir in general.

[citation needed] Other affecting parameters include coal density, initial gas-phase concentration, critical gas saturation, irreducible water saturation, relative permeability to water and gas at conditions of Sw = 1.0 and Sg = 1-Sw irreducible respectively.

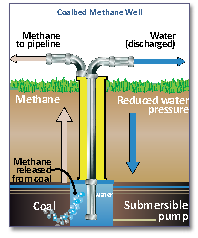

[citation needed] To extract the gas, a steel-encased hole is drilled into the coal seam 100 to 1,500 metres (330 to 4,920 ft) below ground.

The water typically contains dissolved solids such as sodium bicarbonate and chloride but varies depending on the formation geology.

[12] Coalbed methane wells often produce at lower gas rates than conventional reservoirs, typically peaking at near 300,000 cubic feet (8,500 m3) per day (about 0.100 m³/s), and can have large initial costs.

[citation needed] The methane desorption process follows a curve (of gas content vs. reservoir pressure) called a Langmuir isotherm.

[citation needed] The rank of coal has also been linked to CBM content: a vitrinite reflectance of 0.8–1.5% has been found to imply higher productivity of the coalbed.

[citation needed] As with all carbon-based fossil fuels, burning coalbed methane releases carbon dioxide (CO2) into the atmosphere.

[14] Multiple Australian studies have indicated the long term negative environmental effects of coal seam gas extraction, both locally and globally.

[citation needed] Companies like CNX Resources have methane abatement programs to reduce greenhouse gas emissions from active and closed mines.

In 2012 Eastern Star Gas was fined for "discharging polluting water containing high levels of salt into Bohena Creek" in the Pilliga Scrub.

[22] In 2012, the Aspen Skiing Company built a 3-megawatt methane-to-electricity plant in Somerset, Colorado at Oxbow Carbon's Elk Creek Mine.

Although gas in place in Britain's coal fields has been estimated to be 2,900 billion cubic meters, it may be that as little as one percent might be economically recoverable.

IGas Energy became the first in the UK to commercially extract coalbed methane separate from mine venting; as of 2012, the Igas coalbed methane wells at Doe Green, extracting gas for electrical generation, were the only commercial CBM wells in the UK.

Kazakhstan could witness the development of a large coalbed methane (CBM) sector over the coming decades, according to industry professionals.

With the completion of the drilling of 23 vertical production wells by GEECL, coalbed methane became commercially available in India on 14 July 2007 with CNG priced at ₹30 per kg.

GEECL is responsible for Southeast Asia's first CBM station and is also locating one in the West Bengal city of Asansol.

Prashant Modi, President and Chief Operating Officer of GEECL, said, "With the nation requiring higher energy sources to sustain its development pace, we are confident that CBM will play an important role as one of the prime energy sources for the future generations.