Cooling tower

[6][8] These early towers were positioned either on the rooftops of buildings or as free-standing structures, supplied with air by fans or relying on natural airflow.

[6][8] An American engineering textbook from 1911 described one design as "a circular or rectangular shell of light plate—in effect, a chimney stack much shortened vertically (20 to 40 ft. high) and very much enlarged laterally.

At the top is a set of distributing troughs, to which the water from the condenser must be pumped; from these it trickles down over "mats" made of wooden slats or woven wire screens, which fill the space within the tower".

[8] A hyperboloid cooling tower was patented by the Dutch engineers Frederik van Iterson and Gerard Kuypers in the Netherlands on August 16, 1916.

[9] The first hyperboloid reinforced concrete cooling towers were built by the Dutch State Mine (DSM) Emma in 1918 in Heerlen.

In hot climates, large office buildings, hospitals, and schools typically use cooling towers in their air conditioning systems.

The equivalent ton on the cooling tower side actually rejects about 15,000 British thermal units per hour (4.4 kW) due to the additional waste-heat–equivalent of the energy needed to drive the chiller's compressor.

Furthermore, discharging large amounts of hot water may raise the temperature of the receiving river or lake to an unacceptable level for the local ecosystem.

Due to their frequent use in or near residential areas, sound level control is a relatively more important issue for package type cooling towers.

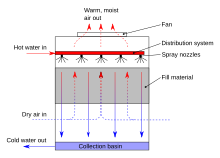

To achieve better performance (more cooling), a medium called fill is used to increase the surface area and the time of contact between the air and water flows.

Both methods create increased surface area and time of contact between the fluid (water) and the gas (air), to improve heat transfer.

A distribution or hot water basin consisting of a deep pan with holes or nozzles in its bottom is located near the top of a crossflow tower.

[citation needed] Disinfectant and other chemical levels in cooling towers and hot tubs should be continuously maintained and regularly monitored.

A normal industrial practice is to use two biocides, such as oxidizing and non-oxidizing types to complement each other's strengths and weaknesses, and to ensure a broader spectrum of attack.

Biocides can reduce other living matter that remains, improving the system and keeping clean and efficient water usage in a cooling tower.

[citation needed] Another very important reason for using biocides in cooling towers is to prevent the growth of Legionella, including species that cause legionellosis or Legionnaires' disease, most notably L. pneumophila,[35] or Mycobacterium avium.

[36] The various Legionella species are the cause of Legionnaires' disease in humans and transmission is via exposure to aerosols—the inhalation of mist droplets containing the bacteria.

[37][38] French researchers found that Legionella bacteria travelled up to 6 kilometres (3.7 mi) through the air from a large contaminated cooling tower at a petrochemical plant in Pas-de-Calais, France.

[39] Drift (or windage) is the term for water droplets of the process flow allowed to escape in the cooling tower discharge.

A typical drift eliminator provides multiple directional changes of airflow to prevent the escape of water droplets.

[40] The US Centers for Disease Control and Prevention (CDC) does not recommend that health-care facilities regularly test for the Legionella pneumophila bacteria.

Scheduled microbiologic monitoring for Legionella remains controversial because its presence is not necessarily evidence of a potential for causing disease.

Also, after an outbreak of legionellosis, health officials agree that monitoring is necessary to identify the source and to evaluate the efficacy of biocides or other prevention measures.

Under certain ambient conditions, plumes of water vapor can be seen rising out of the discharge from a cooling tower, and can be mistaken as smoke from a fire.

One of the results by Haman's group indicated significant dynamic influences of the condensation trails on the surrounding atmosphere, manifested in temperature and humidity disturbances.

[48] Respirable suspended particulate matter, of less than 10 micrometers (μm) in size, can be present in the drift from cooling towers.

[citation needed] Some cooling towers (such as smaller building air conditioning systems) are shut down seasonally, drained, and winterized to prevent freeze damage.

To prevent freezing, the following procedures are used: Cooling towers constructed in whole or in part of combustible materials can support internal fire propagation.

For this reason, some codes and standards[49] recommend that combustible cooling towers be provided with an automatic fire sprinkler system.

[50] Being very large structures, cooling towers are susceptible to wind damage, and several spectacular failures have occurred in the past.