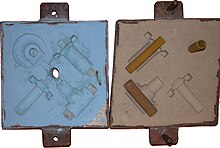

Cope and drag

The sand is then struck level with the top edge of the drag, using a wooden or metal strake.

Then, the cope is placed on the drag, and dowels (or pins) are put in the sand to make holes for the sprue and one or more risers.

Once the metal has cooled enough to solidify, the flask can then be separated again, and the sand removed to reveal the rough casting.

The rough casting is separated from the sprue and riser(s) either by sawing them off, or just breaking the thin metal of the gates and runners.

In some cases the part design is more complicated, and intermediate flasks and mold sections are needed between the cope and drag.