Copper conductor

In a copper atom, the outermost 4s energy zone, or conduction band, is only half filled, so many electrons are able to carry electric current.

When an electric field is applied to a copper wire, the conduction of electrons accelerates towards the electropositive end, thereby creating a current.

The average distance travelled between collisions, defined as the mean free path, is inversely proportional to the resistivity of the metal.

[9][10] Because commercial purity has improved over the last century, copper conductors used in building wire often slightly exceed the 100% IACS standard.

Tensile strength measures the force required to pull an object such as rope, wire, or a structural beam to the point where it breaks.

Copper's high strength resists stretching, neck-down, creep, nicks and breaks, and thereby also prevents failures and service interruptions.

[17] Copper is much heavier than aluminum for conductors of equal current carrying capacity, so the high tensile strength is offset by its increased weight.

Ductility is especially important in metalworking because materials that crack or break under stress cannot be hammered, rolled, or drawn (drawing is a process that uses tensile forces to stretch metal).

This process has adverse effects on electrical systems: terminations can become loose, causing connections to heat up or create dangerous arcing.

For other metal conductors that creep, extra maintenance is required to check terminals periodically and ensure that screws remain tightened to prevent arcing and overheating.

This higher degree of expansion, along with aluminium's lower ductility, can cause electrical problems when bolted connections are improperly installed.

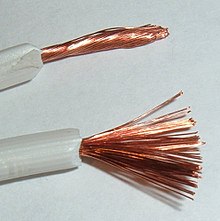

Copper wires in a cable may be bare or they may be plated to reduce oxidation with a thin layer of another metal, most often tin but sometimes gold or silver.

Twisted pair and coaxial cables are designed to inhibit electromagnetic interference, prevent radiation of signals, and to provide transmission lines with defined characteristics.

Oxygen-free coppers are used to resist hydrogen embrittlement when extensive amounts of cold work is needed, and for applications requiring higher ductility (e.g., telecommunications cable).

Patch cables, which connect computers to wall plates, use stranded copper wire because they are expected to be flexed during their lifetimes.

Structured cabling is the general term for 21st century On-premises wiring for high-capacity telephone, video, data-transmission, security, control, and entertainment systems.

Alternatively, wireless systems are a security risk as they can transmit sensitive information to unintended users over similar receiver devices.

[36] Copper is the preferred conductor material for underground transmission lines operating at high and extra-high voltages to 400 kV.

The predominance of copper underground systems stems from its higher volumetric electrical and thermal conductivities compared to other conductors.

These beneficial properties for copper conductors conserve space, minimize power loss, and maintain lower cable temperatures.

[citation needed] Copper continues to dominate low-voltage lines in mines and underwater applications, as well as in electric railroads, hoists, and other outdoor services.

[5] Aluminium, either alone or reinforced with steel, is the preferred conductor for overhead transmission lines due to its lighter weight and lower cost.

[5] Appliance conductors for domestic applications and instruments are manufactured from bunch-stranded soft wire, which may be tinned for soldering or phase identification.

[5] Automotive conductors require insulation that is resistant to elevated temperatures, petroleum products, humidity, fire, and chemicals.

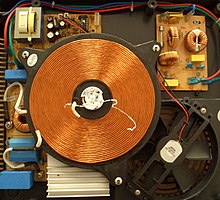

[5][8] Most often, magnetic wire is composed of fully annealed, electrolytically refined copper to allow closer winding when making electromagnetic coils.

[5] High-purity oxygen-free copper grades are used for high-temperature applications in reducing atmospheres or in motors or generators cooled by hydrogen gas.

A copper splice closure is defined by the functional design characteristics and, for the most part, is independent of specific deployment environments or applications.

FBCs provide all of the features and functions expected of a typical splice closure that prevents the intrusion of wind-driven rain, dust, and insects.

[38] Due to the need to increase the transmission of high-speed voice and data signals, the surface quality of copper wire is expected to continue to improve.

Although 6-nines copper (99.9999% pure) has been produced in small quantities, it is extremely expensive and probably unnecessary for most commercial applications such as magnet, telecommunications, and building wire.