Induction cooking

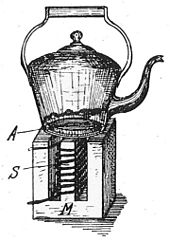

Induction cooking allows high power and very rapid increases in temperature to be achieved: changes in heat settings are instantaneous.

For nearly all models of induction cooktops, a cooking vessel must be made of, or contain, a ferrous metal such as cast iron or some stainless steels.

Induction cooking has good coupling between the pan and the coil and is thus quite efficient, which means it produces less waste heat and it can be quickly turned on and off.

Induction has safety advantages compared to gas stoves and emits no air pollution into the kitchen.

Modern implementations came in the early 1970s, with work done at the Research & Development Center of Westinghouse Electric Corporation.

The surface was a Pyroceram ceramic sheet surrounded by a stainless-steel bezel, upon which four magnetic sliders adjusted four corresponding potentiometers below.

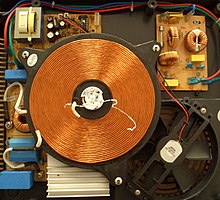

The electronics section was made of four identical modules cooled by a single quiet, low-speed, high-torque fan.

In each of the electronics modules, the 240 V, 60 Hz domestic line power was converted to between 20 V and 200 V of continuously variable DC by a phase-controlled rectifier, which was then converted to 27 kHz 30 A (peak) AC by two arrays of six paralleled Motorola automotive-ignition transistors in a half-bridge configuration driving a series-resonant LC oscillator, of which the inductor component was the induction-heating coil and its load, the cooking pan.

The unit also had a self-cleaning oven, solid-state kitchen timer and capacitive-touch control buttons, advanced for the time.

In 2009 Panasonic developed an all-metal induction cooker that used frequencies up to 120 kHz,[10] three to five times higher than other cooktops, to work with non-ferrous metal cookware.

The coil is mounted under the cooking surface, and a low-radio-frequency (typically ~25–50 kHz[1]) alternating current is passed through it.

Conversely, increased skin effect in the cookware results in more efficient coupling, which is one of the factors making ferrous materials[11] preferable.

This helps prevent the pan from severely overheating if accidentally heated empty or boiled dry, but some models can allow the induction cooker to maintain a target temperature.

Induction cookers are easy to clean because the cooking surface is flat and smooth and does not usually get hot enough to make spilled food burn and stick.

Electromagnetically induced acoustic noise and vibration (a high-pitched hum or buzz) may be produced, especially at high power, if the cookware has loose parts or if the layers of the pot are not well bonded to each other; cookware with welded-in cladding layers and solid riveting is less likely to produce this type of noise.

Persons with artificial pacemakers or other electronic medical implants are usually instructed to avoid sources of magnetic fields.

Cookware should have a flat bottom since the magnetic field strength (heating power) drops rapidly with distance from the surface.

Induction cooking surfaces work well with any pans with a high ferrous metal content at the base.

Cast iron frying pans work well with induction cooking surfaces, although the material is not as good a thermal conductor as aluminum.

These ferromagnetic materials have a high magnetic permeability which greatly decreases the skin depth, concentrating the current in a very thin layer at the surface of the metal bottom of the pan.

Panasonic in 2009 developed a consumer induction cooker that uses a higher-frequency magnetic field of 60 kHz or higher, and a different oscillator circuit design, to allow use with non-ferrous metals as well, including aluminum, multilayer and copper pots and pans.

[18][19] In 2017 Panasonic released a single-burner counter top "all metal" unit, using their trade name "Met-All", aimed at commercial kitchens.

After 15 minutes of operation at this lower power setting, the cooktop is turned off and the heat energy in the test block is measured.

Wasted energy terms such as residual unused heat (retained by solid hot-plates, ceramic or coil at the end of the test), and losses from convection and radiation by hot surfaces (including the ones of the block itself) are disregarded.

In 2013 and 2014 DOE developed and proposed new test procedures to allow direct comparison of energy transfer efficiency among induction, electric resistance, and gas cooking tops and ranges.

For comparable (large) cooking elements the following efficiencies were measured with ±0.5% repeatability: 70.7% - 73.6% for induction, 71.9% for electric coil, 43.9% for gas.

If a pan boils dry it can get extremely hot – a thermostat in the surface will turn off the power if it senses overheating to prevent cooker failures and potential fires.

Induction ranges may be applicable in commercial restaurant kitchens, with lower installation, ventilation and fire suppression equipment costs.

[27] Drawbacks for commercial use include possible breakages of the glass cook-top, higher initial cost and the requirement for magnetic cookware.

[citation needed] In April 2010, The New York Times reported that "In an independent survey [in 2009] by the market research company Mintel of 2,000 Internet users who own appliances, only 5 percent of respondents said they had an induction range or cooktop.