Crucible

The form of the crucible has varied through time, with designs reflecting the process for which they are used, as well as regional variation.

The main purpose of the crucible during this period was to keep the ore in the area where the heat was concentrated to separate it from impurities before shaping.

[6] A crucible furnace dating to 2300–1900 BC for bronze casting has been found at a religious precinct of Kerma.

[citation needed] The Roman period shows technical innovations, with crucibles for new methods used to produce new alloys.

[10] Brass is made by mixing solid copper metal with zinc oxide or carbonate which comes in the form of calamine or smithsonite.

[12] This reaction has to take place in a part-closed or closed container otherwise the zinc vapor would escape before it can react with the copper.

Smelting and melting of copper and its alloys such as leaded bronze was done in crucibles similar to those of the Roman period which have thinner walls and flat bases to sit within the furnaces.

The technology for this type of smelting started to change at the end of the Medieval period with the introduction of new tempering material for the ceramic crucibles.

The cementation process, which was lost from the end of the Roman to the early Medieval period, continued in the same way with brass.

[15] However, during this period a vast and highly important technological innovation happened using the cementation process, the production of crucible steel.

These early crucibles would only produce a small amount of steel as they would have to be broken once the process has finished.

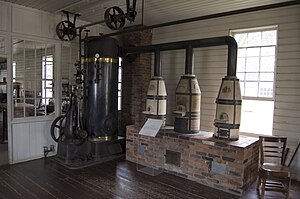

The main types used during the Post Medieval period are the Hessian crucibles which were made in the Hesse region in Germany.

These are triangular vessels made on a wheel or within a mold using high alumina clay and tempered with pure quartz sand.

[19] Another vessel used for the same process is a scorifier which is similar to a cupel but slightly larger and removes the lead and leaves the noble metals behind.

[21] However, chemical reactions with the material in the crucible must be kept in mind; the emergence of melting point-lowering eutectic systems is an especially important consideration.

The lids are typically loose-fitting in order to allow gases to escape during the heating of a sample inside.

For this reason, the porcelain crucible and lid is also pre-fired (pre-heating to high temperature) to constant mass before the pre-weighing.