Delta robot

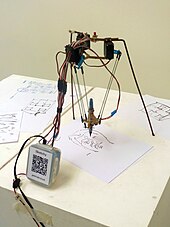

The key design feature is the use of parallelograms in the arms, which maintains the orientation of the end effector.

[4] The delta robot (a parallel arm robot) was invented in the early 1980s by a research team led by professor Reymond Clavel at the École Polytechnique Fédérale de Lausanne (EPFL, Switzerland).

[5] After a visit to a chocolate maker, a team member wanted to develop a robot to place pralines in their packages.

[6] The purpose of this new type of robot was to manipulate light and small objects at a very high speed, an industrial need at that time.

Having all the arms connected together to the end-effector increases the robot stiffness, but reduces its working volume.

[13][14] These offer advantages over conventional leadscrew-based 3D printers of quicker access to a larger build volume for a comparable investment in hardware.