3D printing

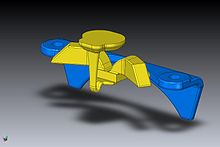

Agile tooling uses a cost-effective and high-quality method to quickly respond to customer and market needs, and it can be used in hydroforming, stamping, injection molding and other manufacturing processes.

The term ink as used in is intended to include not only dye or pigment-containing materials, but any flowable substance or composition suited for application to the surface for forming symbols, characters, or patterns of intelligence by marking.

[16] In April 1980, Hideo Kodama of Nagoya Municipal Industrial Research Institute invented two additive methods for fabricating three-dimensional plastic models with photo-hardening thermoset polymer, where the UV exposure area is controlled by a mask pattern or a scanning fiber transmitter.

[26] In 1983, Robert Howard started R.H. Research, later named Howtek, Inc. in Feb 1984 to develop a color inkjet 2D printer, Pixelmaster, commercialized in 1986, using Thermoplastic (hot-melt) plastic ink.

One Howtek member, Richard Helinski (patent US5136515A, Method and Means for constructing three-dimensional articles by particle deposition, application 11/07/1989 granted 8/04/1992) formed a New Hampshire company C.A.D-Cast, Inc, name later changed to Visual Impact Corporation (VIC) on 8/22/1991.

Another employee Herbert Menhennett formed a New Hampshire company HM Research in 1991 and introduced the Howtek, Inc, inkjet technology and thermoplastic materials to Royden Sanders of SDI and Bill Masters of Ballistic Particle Manufacturing (BPM) where he worked for a number of years.

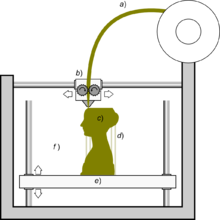

The technology used by most 3D printers to date—especially hobbyist and consumer-oriented models—is fused deposition modeling, a special application of plastic extrusion, developed in 1988 by S. Scott Crump and commercialized by his company Stratasys, which marketed its first FDM machine in 1992.

[61] Furthermore, the capabilities of 3D printing have extended beyond traditional manufacturing, like lightweight construction,[62] or repair and maintenance[63] with applications in prosthetics,[64] bioprinting,[65] food industry,[66] rocket building,[67] design and art[68] and renewable energy systems.

[90] Some printable polymers, such as acrylonitrile butadiene styrene (ABS), allow the surface finish to be smoothed and improved using chemical vapor processes[91] based on acetone or similar solvents.

Charles Hull filed the first patent on August 8, 1984, to use a UV-cured acrylic resin using a UV-masked light source at UVP Corp to build a simple model.

Masked lamp UV-cured resin was also introduced by Cubital's Itzchak Pomerantz in the Soldier 5600, Carl Deckard's (DTM) laser sintered thermoplastic powders, and adhesive-laser cut paper (LOM) stacked to form objects by Michael Feygin before 3D Systems made its first announcement.

[128] The binder jetting 3D printing technique involves the deposition of a binding adhesive agent onto layers of material, usually powdered, and then this "green" state part may be cured and even sintered.

To produce a part, the printer builds the model using a head that moves over the platform base to spread or deposit alternating layers of powder (plaster and resins) and binder.

In 2005 Mcor Technologies Ltd developed a different process using ordinary sheets of office paper, a tungsten carbide blade to cut the shape, and selective deposition of adhesive and pressure to bond the prototype.

Laser engineered net shaping (LENS), which was developed by Sandia National Labs, is one example of the powder-fed directed-energy deposition process for 3D printing or restoring metal parts.

The use of additive manufacturing for serialized production of orthopedic implants (metals) is also increasing due to the ability to efficiently create porous surface structures that facilitate osseointegration.

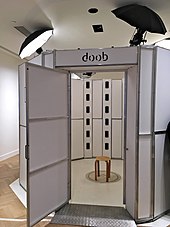

As of 2012[update], 3D bio-printing technology has been studied by biotechnology firms and academia for possible use in tissue engineering applications in which organs and body parts are built using inkjet printing techniques.

In this process, layers of living cells are deposited onto a gel medium or sugar matrix and slowly built up to form three-dimensional structures including vascular systems.

Circuit board manufacturing involves multiple steps which include imaging, drilling, plating, solder mask coating, nomenclature printing and surface finishes.

The benefits of 3D printing would be that the final outline is defined from the beginning, no imaging, punching or lamination is required and electrical connections are made with the silver polymer which eliminates drilling and plating.

Patents cover inventions including processes, machines, manufacturing, and compositions of matter and have a finite duration which varies between countries, but generally 20 years from the date of application.

[254] Polymer feedstock materials can release ultrafine particles and volatile organic compounds (VOCs) if sufficiently heated, which in combination have been associated with adverse respiratory and cardiovascular health effects.

3D printers also contain many moving parts that include stepper motors, pulleys, threaded rods, carriages, and small fans, which generally do not have enough power to cause serious injuries but can still trap a user's finger, long hair, or loose clothing.

[259] The futurologist Jeremy Rifkin[260] claimed that 3D printing signals the beginning of a third industrial revolution,[261] succeeding the production line assembly that dominated manufacturing starting in the late 19th century.

[264] Finally, given the ease with which certain objects can now be replicated, it remains to be seen whether changes will be made to current copyright legislation so as to protect intellectual property rights with the new technology widely available.

And the trends are all in the wrong direction, particularly for the less skilled, as the capacity of capital embodying artificial intelligence to replace white-collar as well as blue-collar work will increase rapidly in the years ahead."

Summers recommends more vigorous cooperative efforts to address the "myriad devices" (e.g., tax havens, bank secrecy, money laundering, and regulatory arbitrage) enabling the holders of great wealth to "a paying" income and estate taxes, and to make it more difficult to accumulate great fortunes without requiring "great social contributions" in return, including: more vigorous enforcement of anti-monopoly laws, reductions in "excessive" protection for intellectual property, greater encouragement of profit-sharing schemes that may benefit workers and give them a stake in wealth accumulation, strengthening of collective bargaining arrangements, improvements in corporate governance, strengthening of financial regulation to eliminate subsidies to financial activity, easing of land-use restrictions that may cause the real estate of the rich to keep rising in value, better training for young people and retraining for displaced workers, and increased public and private investment in infrastructure development—e.g., in energy production and transportation.

This process of labor substitution and disintermediation has been underway for some time in service sectors—think of ATMs, online banking, enterprise resource planning, customer relationship management, mobile payment systems, and much more.

In his view, the vast majority of the cost of digital technologies comes at the start, in the design of hardware (e.g. 3D printers) and, more importantly, in creating the software that enables machines to carry out various tasks.

In his view, production will not disappear, but it will be less labor-intensive, and all countries will eventually need to rebuild their growth models around digital technologies and the human capital supporting their deployment and expansion.