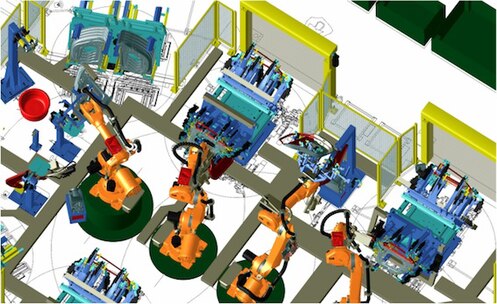

Digital manufacturing

[3] These models can be classified into the following:[3] Applications of simulation can be assigned to:[3] Digital manufacturing systems often incorporate optimization capabilities to reduce time, cost, and improve the efficiency of most processes.

[4] In addition, many technologies analyze data from simulations in order to calculate a design that is optimal before it is even built.

Econometric models have found that each newly installed robot displaces 1.6 manufacturing workers on average.

Those models also have forecasted that by 2030 as many as 20 million additional manufacturing jobs worldwide could be displaced due to robotization.

However, every digital manufacturing process involves the use of computerized numerical controlled machines (CNC).

This type of system must be cloud computing-based, be accessible from mobile devices, and must be able to manage complex information.