Armature (electrical)

The pole piece of a permanent magnet or electromagnet and the moving, iron part of a solenoid, especially if the latter acts as a switch or relay, may also be referred to as armatures.

Armature reaction drop is the effect of a magnetic field on the distribution of the flux under main poles of a generator.

The brushes of a generator must be set in the neutral plane; that is, they must contact segments of the commutator that are connected to armature coils having no induced emf.

If the brushes were contacting commutator segments outside the neutral plane, they would short-circuit "live" coils and cause arcing and loss of power.

The first method is to shift the position of the brushes so that they are in the neutral plane when the generator is producing its normal load current.

in the other method, special field poles, called interpoles, are installed in the generator to counteract the effect of armature reaction.

The brush-setting method is satisfactory in installations in which the generator operates under a fairly constant load.

If the load varies to a marked degree, the neutral plane will shift proportionately, and the brushes will not be the correct position at all times.

The brush-setting method is the most common means of correcting for armature reaction in small generators (those producing approximately 1,000 W or less).

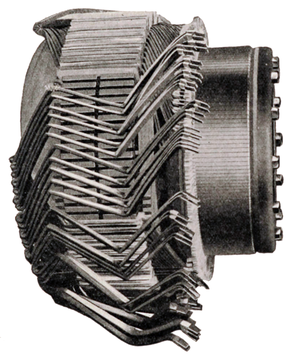

Coils of the winding are distributed over the entire surface of the air gap, which may be the rotor or the stator of the machine.

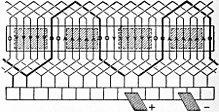

So, for a given rating of machine, a wave winding is more suitable for large currents and low voltages.