Drain-waste-vent system

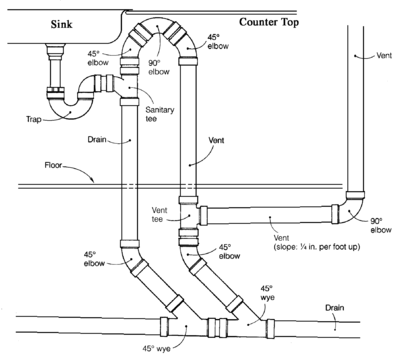

It includes venting to the exterior environment to prevent a vacuum from forming and impeding fixtures such as sinks, showers, and toilets from draining freely, and employs water-filled traps to block dangerous sewer gasses from entering a plumbed structure.

For such drainage systems to work properly it is crucial that neutral air pressure be maintained within all pipes, allowing free gravity flow of water and sewage through drains.

In situations where a downward slope out of a building en route to a treatment system cannot be created, a special collection sump pit and grinding lift "sewage ejector" pump are needed.

[1] Without a vent, negative pressure can slow the flow of water leaving the system, resulting in clogs, or cause siphonage to empty a trap.

An additional risk of pressurizing a system ahead of a waste stream is the potential for it to overwhelm a downstream trap and force tainted water into its fixture.

Adding a vent connection within a long horizontal run with little slope will aid flow, and when used with a cleanout allows for better serviceability.

The advent of PVC and solvent welding adhesives, which secure fittings against leakage and separation by melting the material into itself, has profoundly simplified and made installing a DWV system less expensive.