Drill bushing

This facilitates the ability to do multiple machining operations that require different inner diameter (ID) bushings, such as drilling and reaming.

The tail may be bent at the end so it can lock around the edge of the jig plate or it may be left straight if it can butt up against another object.

[5] Customary bushings are specified using the following specification layout:[3] Where the ID is specified as a decimal, drill letter size, drill number size, or fraction; the OD is an integer that relates to a multiple of a 1⁄64th of an inch (0.40 mm); the length is an integer that relates to a multiple of a 1⁄16th of an inch.

The type is a letter referring to the following:[3] The following two tables give the tolerances for the ID and OD.

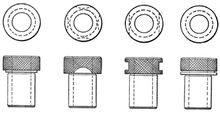

In this case one large renewable bushing can be made with two (or more) holes in the proper location (the first example in the image).

It is a hardened piece of right angle steel that screws to the jig plate and is located with dowel pins.