E-diesel

Currently, e-diesel is created at two sites: by an Audi research facility Germany in partnership with a company named Sunfire, and in Texas.

The current process involves high-temperature electrolysis powered by electricity generated from renewable energy sources to split water into hydrogen and oxygen.

The next two chemical processes to create a liquid energy carrier called blue crude are done at a temperature of 220 °C (428 °F) and a pressure of 25 bars (2,500 kPa).

At that point, the sorbent is introduced with 95 °C (203 °F) heat in a desorption cycle to drive out the high-purity carbon dioxide that can be used during the conversion step of the blue crude generation process.

[5] In future designs,[11][12] the oxygen by-product may be combined with renewable natural gas in the oxidative coupling of methane to ethylene:[13][14] The reaction is exothermic (∆H = -280 kJ/mol) and occurs at high temperatures (750–950 ˚C).

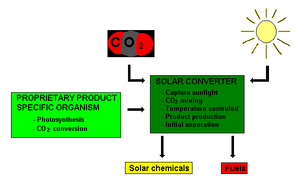

Joule's planned plant in New Mexico involved the use of genetically modified microorganisms in bright sunlight to act as catalyst for the conversion of carbon dioxide and salty water into hydrocarbons.

It produces the fuel using photosynthesis, the same process that multi-cellular green plants use, to make sugars and other materials from water, carbon dioxide, and sunlight.