Electron beam-induced deposition

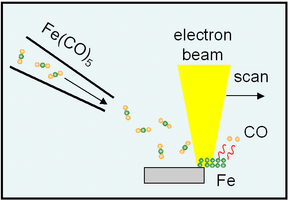

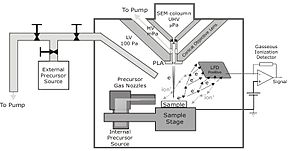

Precursor materials are typically liquid or solid and gasified prior to deposition, usually through vaporization or sublimation, and introduced, at accurately controlled rate, into the high-vacuum chamber of the electron microscope.

[3][4] In the presence of the precursor gas, the electron beam is scanned over the substrate, resulting in deposition of material.

To overcome this problem, compensation algorithms can be applied, which is typical for electron beam lithography.

As of 2008 the range of materials deposited by EBID included Al, Au, amorphous carbon, diamond, Co, Cr, Cu, Fe, GaAs, GaN, Ge, Mo, Nb, Ni, Os, Pd, Pt, Rh, Ru, Re, Si, Si3N4, SiOx, TiOx, W,[5] and was being expanded.

The most popular precursors for deposition of elemental solids are metal carbonyls of Me(CO)x structure or metallocenes.

They are easily available, however, due to incorporation of carbon atoms from the CO ligands, deposits often exhibit a low metal content.