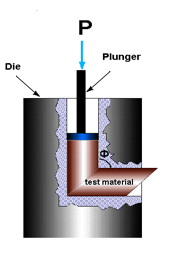

Equal channel angular extrusion

[2] In industrial metalworking, it is an extrusion process,[3] The technique is able to refine the microstructure of metals and alloys, thereby improving their strength according to the Hall-Petch relationship.

[4] ECAE is unique because significant cold work can be accomplished without reduction in the cross sectional area of the deformed workpiece.

In conventional deformation processes like rolling, forging, extrusion, and drawing, strain is introduced by reduction in the cross sectional area.

Because the cross section remains the same, a work piece can be extruded multiple times with each pass introducing additional strain.

According to the rotation angle and direction between next passes, there can be four fundamental process routes named A, Ba, Bc, and C: The behave during deformation and flow of the material, are analyzed by scientists and there are many articles on computer simulation, finite element method is one of the important approaches to understand the deformation occurring in the ECAE process.