Microstructure

[1] The microstructure of a material (such as metals, polymers, ceramics or composites) can strongly influence physical properties such as strength, toughness, ductility, hardness, corrosion resistance, high/low temperature behaviour or wear resistance.

A microstructure's influence on the mechanical and physical properties of a material is primarily governed by the different defects present or absent of the structure.

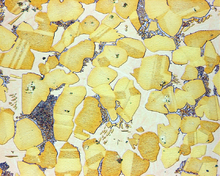

Galvanized steel, such as the casing of a lamp post or road divider, exhibits a non-uniformly colored patchwork of interlocking polygons of different shades of grey or silver.

Zinc and lead are two common metals which form large crystals (grains) visible to the naked eye.

The atoms in each grain are organized into one of seven 3d stacking arrangements or crystal lattices (cubic, tetrahedral, hexagonal, monoclinic, triclinic, rhombohedral and orthorhombic).

The direction of alignment of the matrices differ between adjacent crystals, leading to variance in the reflectivity of each presented face of the interlocked grains on the galvanized surface.

Pores with large coordination number (surrounded by many particles) tend to grow during the thermal process.

[14] Those processes rely in the principle that an increase in temperature will induce the reduction or annihilation of pores.

[15] Hot isostatic pressing (HIP) is a manufacturing process, used to reduce the porosity of metals and increase the density of many ceramic materials.

However, some systems also associate gas pumping to the process to achieve the required pressure level.

[17] When castings are treated with HIP, the simultaneous application of heat and pressure eliminates internal voids and microporosity through a combination of plastic deformation, creep, and diffusion bonding; this process improves fatigue resistance of the component.