Eutectic bonding

[citation needed] Eutectic alloys are deposited by sputtering, dual source evaporation or electroplating.

[2] Eutectic bonding to transfer epitaxial materials such as GaAs-AlGaAs onto silicon (Si) substrates with high yields for the general purpose of optoelectronics integration with Si electronics as well as to overcome fundamental issues such as lattice mismatch in hetero-epitaxy, was developed and reported by Venkatasubramanian et al. in 1992, and the performance of eutectic-bonded GaAs-AlGaAs materials for solar cells was further validated and reported by the same group in 1994.

[3][4] Eutectic bonding is able to produce hermetically sealed packages and electrical interconnection within a single process (compare ultrasonic images).

[5] This bonding procedure is most commonly used for Si or glass wafers that are coated with an Au/Al film and partly with adhesive layer (compare with following image).

The Si-Au couple has the advantages of an exceptionally low eutectic temperature, an already widespread use in die bonding and the compatibility with Al interconnects.

[10] Compared to glass frit bonding, the advantage sticks out that the reduction of seal ring geometries, an increase of the hermeticity levels and a shrinking of device size is possible.

The use of eutectic alloy brings the advantage of providing electrical conduction and interfacing with redistribution layers.

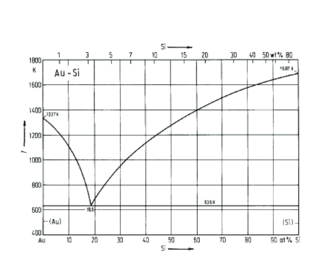

The bonding happens at a specific weight-% and temperature, e.g. 370 °C at 2.85 wt-% Si for Au intermediate layer (compare to phase diagram).

[1] An additional method for the removal of unwanted surface films, i.e. oxide, is applying ultrasound during the attachment process.

[10] The diffusion barrier avoids interaction between Au and Ti/Cr and requires higher temperatures to form a reliable and uniform bond.

[12] The removal of contamination, on the for silicon most established Au layer, can be done using water flushing and wafer heating.

[incomprehensible][1] The contacting of the substrates is applied directly after the pre-treatment of the surfaces to avoid oxide regeneration.

The bonding procedure for oxidizing metals (not Au) generally takes place in a reduced atmosphere of 4% hydrogen and an inert carrier gas flow, e.g. nitrogen.

[17] The material mix is solidified when the temperature decreases below eutectic point or the concentration ratio changes (for Si-Au: T < 370 °C).