Fed-batch culture

By adding such substrates properly lag-time can be shortened and the inhibition of the cell growth markedly reduced.

Glucose effect (Crabtree effect)[1] In the production of baker's yeast from malt wort or molasses it has been recognized since early 1900s that ethanol is produced even in the presence of sufficient dissolved oxygen (DO) if an excess of sugar is present in the culture liquid.

Catabolite repression[1] When a microorganism is provided with a rapidly metabolizable carbon-energy source such as glucose, the resulting increase in the intracellular concentration of ATP leads to the repression of enzyme(s) biosynthesis, thus causing a slower metabolization of the energy source.

Slow feeding of glucose in penicillin fermentation by Penicillium chrysogenum is a classical example in the category.

In such a bioprocess, the accumulation of the desired metabolite can be maximized by growing the mutant on a limited amount of the required nutrient.

To cultivate the mutant on a low concentration of the required nutrient, it is fed to the batch culture at a controlled rate.

An example is lysine production with homoserine- or threonine/methionine-requiring mutant of Corynebacterium glutamicum being lacking for homoserine dehydrogenase gene.

Keeping the concentration of this compound as low as possible (while still allowing for sufficient cell growth) permits continued expression of the regulated gene.

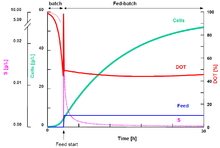

Extension of operation time, supplement of water lost by evaporation, and decreasing viscosity of culture broth[1] The fed-batch strategy is typically used in bio-industrial processes to reach a high cell density in the bioreactor.

[7][8][9][10] The controlled addition of the nutrient directly affects the growth rate of the culture and helps to avoid overflow metabolism (formation of side metabolites, such as acetate for Escherichia coli, lactic acid in mammalian cell cultures, ethanol in Saccharomyces cerevisiae), oxygen limitation (anaerobiosis).