Flow control valve

Automatic control valves do not require an external power source, meaning that the fluid pressure is enough to open and close them.

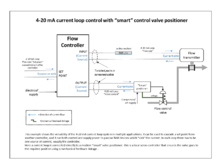

Process plants consist of hundreds, or even thousands, of control loops all networked together to produce a product to be offered for sale.

Each of these control loops is designed to keep some important process variable, such as pressure, flow, level, or temperature, within a required operating range to ensure the quality of the end product.

[1] To reduce the effect of these load disturbances, sensors and transmitters collect information about the process variable and its relationship to some desired set point.

The control valve manipulates a flowing fluid, such as gas, steam, water, or chemical compounds, to compensate for the load disturbance and keep the regulated process variable as close as possible to the desired set point.