Respirator

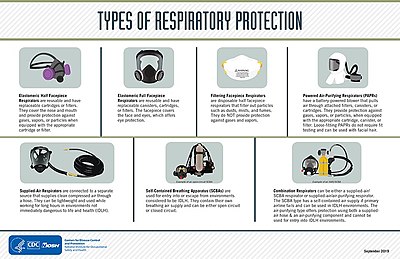

A respirator is a device designed to protect the wearer from inhaling hazardous atmospheres including lead fumes, vapors, gases and particulate matter such as dusts and airborne pathogens such as viruses.

[1] In the 16th century, Leonardo da Vinci suggested that a finely woven cloth dipped in water could protect sailors from a toxic weapon made of powder that he had designed.

[7] Inventors in Europe included John Stenhouse, a Scottish chemist, who investigated the power of charcoal in its various forms, to capture and hold large volumes of gas.

[9] Also in 1874, Samuel Barton patented a device that 'permitted respiration in places where the atmosphere is charged with noxious gases, or vapors, smoke, or other impurities.

'[10][11] In the late 19th century, Miles Philips began using a "mundebinde" ("mouth bandage") of sterilized cloth which he refined by adapting a chloroform mask with two layers of cotton mull.

[12] In the winter of 1910, Wu was given instructions from the Foreign Office of the Imperial Qing court[13] in Peking, to travel to Harbin to investigate an unknown disease that killed 99.9% of its victims.

The German army successfully used poison gas for the first time against Allied troops at the Second Battle of Ypres, Belgium on April 22, 1915.

An example of an early respirator standard, Type A, established in 1926, was intended to protect against mechanically generated dusts produced in mines.

However, prior to the Hawks Nest Tunnel Disaster, these standards were merely advisory, as the USBM had no enforcement power at the time.

[N2] The standard for N95 respirators includes, but is not limited to, a filtration of at least 95% under a 0.3 micrometer[C4] 200 milligram test load of sodium chloride.

[C1][N1] NIOSH certifies B Readers, people qualified to testify or provide evidence in mesothelioma personal injury lawsuits,[35] in addition to regulating respirators.

Combined with testimony that the plaintiff rarely wore a respirator around asbestos, the lack of evidence, and the limitation of liability from static NIOSH approval, the case was overturned.

Unsealed versions may be used when air is supplied at a rate which prevents ambient gas from reaching the nose or mouth during inhalation.

Manufacturers have different methods for performing seal checks and wearers should consult the specific instructions for the model of respirator they are wearing.

The fitting characteristic of a respirator is the ability of the mask to separate a worker's respiratory system from ambient air.

A surgical mask is a loosely-placed, unsealed barrier, meant to stop droplets, and other liquid-borne particles from the mouth and nose that may contain pathogens.

In the United States, the National Institute for Occupational Safety and Health defines the categories of particulate filters according to their NIOSH air filtration rating.

(For example, US NIOSH-approved respirators never include earloops because they don't provide enough support to establish a reliable, airtight seal.)

[57] Chemical cartridges and gas mask canisters remove gases, volatile organic compounds (VOCs), and other vapors from breathing air by adsorption, absorption, or chemisorption.

A typical organic vapor respirator cartridge is a metal or plastic case containing from 25 to 40 grams of sorption media such as activated charcoal or certain resins.

[81][72][82] A self-contained self-rescue device, SCSR, self-contained self-rescuer, or air pack is a type of closed-circuit SCBA[84] with a portable oxygen source for providing breathable air when the surrounding atmosphere lacks oxygen or is contaminated with toxic gases, e.g. carbon monoxide.

Self-rescuers are intended for use in environments such as coal mines where there is a risk of fire or explosion, and in a location where no external rescue may be available for some time – the wearer must make their own way to safety, or to some pre-equipped underground refuge.

[86] This "simulated workplace protection factor" (SWPF) was said to be problematic: By inference, these data are equally at odds with the protection factors established by OSHA for various types of respirator, which were based on QNFT [quantitative fit testing] data obtained by the Los Alamos National Laboratory in the 1970s.

However, NIOSH pointed out that the poor adherence to OSHA regulations on exposure-level monitoring by employers, as well as lack of expertise in interpreting the collected data, would likely result in more workers being put at risk.

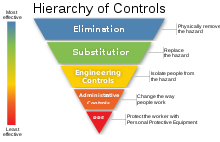

[100] The Hierarchy of Controls, noted as part of the Prevention Through Design initiative started by NIOSH with other standards bodies, is a set of guidelines emphasizing building in safety during design, as opposed to ad-hoc solutions like PPE, with multiple entities providing guidelines on how to implement safety during development[101] outside of NIOSH-approved respirators.

US Government entities currently and formerly involved in the regulation of respirators follow the Hierarchy of Controls, including OSHA[102] and MSHA.

[103] However, some HOC implementations, notably MSHA's, have been criticized for allowing mining operators to skirt engineering control noncompliance by requiring miners to wear respirators instead if the permissible exposure limit (PEL) is exceeded, without work stoppages, breaking the hierarchy of engineering controls.

Another concern was fraud related to the inability to scrutinize engineering controls,[104][105] unlike NIOSH-approved respirators, like the N95, which can be fit tested by anyone, are subject to the scrutiny of NIOSH, and are trademarked and protected under US federal law.

[111][112] A U.S. Department of Labor study[113] showed that in almost 40 thousand American enterprises, the requirements for the correct use of respirators are not always met.

[125] Complaints have been leveled at early LANL NIOSH fit test panels (which included primarily military personnel) as being unrepresentative of the broader American populace.