Darrieus wind turbine

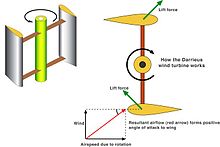

The turbine consists of a number of curved aerofoil blades mounted on a rotating shaft or framework.

This force can be projected inwards past the turbine axis at a certain distance, giving a positive torque to the shaft, thus helping it to rotate in the direction it is already travelling in.

The aeronautical terms lift and drag are, strictly speaking, forces across and along the approaching net relative airflow respectively, so they are not useful here.

In particular, almost all Darrieus turbines have resonant modes where, at a particular rotational speed, the pulsing is at a natural frequency of the blades that can cause them to (eventually) break.

In this configuration, the Darrieus design is theoretically less expensive than a conventional type, as most of the stress is in the blades which torque against the generator located at the bottom of the turbine.

The only forces that need to be balanced out vertically are the compression load due to the blades flexing outward (thus attempting to "squeeze" the tower), and the wind force trying to blow the whole turbine over, half of which is transmitted to the bottom and the other half of which can easily be offset with guy wires.

By contrast, a conventional design has all of the force of the wind attempting to push the tower over at the top, where the main bearing is located.

Traditional designs assume that the wing tip is at least 40 m from ground at lowest point to maximize energy production and lifetime.

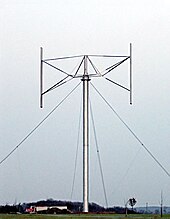

One of the more common types is the H-rotor,[1][2][3] also called the Giromill or H-bar design, in which the long "egg beater" blades of the common Darrieus design are replaced with straight vertical blade sections attached to the central tower with horizontal supports.

The Cycloturbine also has the advantage of being able to self-start, by pitching the "downwind moving" blade flat to the wind to generate drag and start the turbine spinning at a low speed.

Since the wind pulls each blade around on both the windward and leeward sides of the turbine, this feature spreads the torque evenly over the entire revolution, thus preventing destructive pulsations.

This design is used by the Turby, Urban Green Energy, Enessere, Aerotecture and Quiet Revolution brands of wind turbine.