Hot-bulb engine

Vigorous ignition takes place only when sufficient oxygen is supplied to the hot-bulb chamber on the compression stroke of the engine.

Similar engines, for agricultural and marine use, were built by J. V. Svensons Motorfabrik, Bolinders, Lysekils Mekaniska Verkstad, AB Pythagoras and many other factories in Sweden.

Manufacturers in Europe, Scandinavia and in the United States (and some British firms including Petter, Gardner and Allen) built engines working on the two-stroke cycle with crankcase scavenging.

Another method was the inclusion of a spark plug and vibrator-coil ignition; the engine would be started on petrol (gasoline) and switched over to oil after warming to running temperature.

This was a limiting factor on the power output of hot-bulb engines and in order to circumvent this limit some hot-bulb engines feature a system whereby water is dripped into the air intake to reduce the temperature of the air charge and counteract pre-ignition, thus allowing higher power outputs.

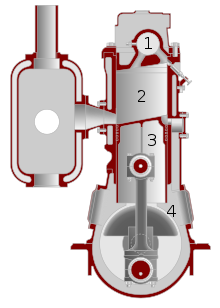

The compression stroke mostly serves to create a turbulent movement of air from the cylinder into the vaporizer, which mixes with the pre-vaporized fuel oil.

This mixing, and the increase in oxygen content as the air is lightly compressed into the vaporizer, causes the fuel oil vapour to spontaneously ignite.

The charge of air on top of the piston is driven into the vaporiser, where it mixes with the atomised fuel and combustion takes place.

The piston then reaches the bottom of its stroke and begins to rise again, drawing a fresh charge of air into the crankcase and completing the cycle.

There were also designs that employed a scavenge pump or similar to remove oil from the crankcase and return it to the lubricating-oil reservoir.

The lack of valves and the doubled-up working cycle also means that a two-stroke hot-bulb engine can run equally well in both directions.

Lanz Bulldog tractors featured a dial, mechanically driven by the engine, that showed a spinning arrow.

Condenserless steam engines achieved an average thermal efficiency (the fraction of generated heat that is actually turned into useful work) of around 6%.

Boilers require at least one person to add water and fuel as needed and to monitor pressure to prevent overpressure and a resulting explosion.

A more common problem was that if the water level in the boiler of a steam engine dropped too low, the lead plug in the crown of the furnace would melt, extinguishing the fire.

If the cooling water ran low, the engine would seize through overheating — a major problem, but it carried no danger of explosion.

this multi-fuel ability has led to an interest in using hot-bulb engines in developing nations, where they can be run on locally produced biofuel.

[10] Due to the lengthy pre-heating time, hot-bulb engines usually started easily, even in extremely cold conditions.

J. V. Svenssons Motorfabrik, in Augustendal in Stockholm, Sweden, used hot-bulb engines in their Typ 1 motor plough, produced from 1912 to 1925.

Munktells Mekaniska Verkstads AB, in Eskilstuna, Sweden, produced agricultural tractors with hot-bulb engines from 1913 onwards.

In America, Standard, Weber, Reid, Stickney, Oil City, and Fairbanks Morse built hot-bulb engines.

This made the hot-bulb engine difficult to adapt to automotive uses, other than vehicles such as tractors, where speed was not a major requirement.

Generator sets driven by hot-bulb engines were installed in numerous large houses in Europe, especially in rural areas, as well as in factories, theatres, lighthouses, radio stations and many other locations where a centralised electrical grid was not available.

To make a hot bulb engine capable of powering a ship or locomotive, it would have been prohibitively large and heavy.

Parts of the fuel charge throughout the hot bulb would ignite at different times, often before the piston had completed the compression stroke.

The last large-scale manufacturer of hot bulb engines stopped producing them in the 1950s and they are now virtually extinct in commercial use, except in very remote areas of the developing world.

In hot bulb engines, fuel is injected at low pressure, using a more economical and more reliable, and simpler configuration.

[14][15] With technology developed by Robert Bosch GmbH pump and injector systems could be built to run at a much higher pressure.

[12] Glowplugs finally replaced the preheating with a blowtorch methods and engine speeds were increased, resulting in what is now classified as an indirect-injection diesel.

The fuel pump was usually made with a brass housing and steel plunger, operating with a variable stroke length.

Four-stroke, 14 HP running at the

Great Dorset Steam Fair in 2008

The hot bulb is immediately above the front axle, mounted on the front of the cylinder block.