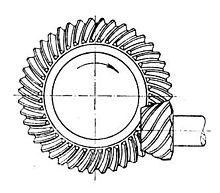

Spiral bevel gear

The helical design produces less vibration and noise than conventional straight-cut or spur-cut gear with straight teeth.

[citation needed] They are considerably stronger in that any load is conveyed through multiple teeth simultaneously.

Hypoid gears are stronger, operate more quietly and can be used for higher reduction ratios, however they also have some sliding action along the teeth, which reduces mechanical efficiency, the energy losses being in the form of heat produced in the gear surfaces and the lubricating fluid.

The hypoid gear is also commonly used in some railcar transmissions with diesel power units - where the engine and gearbox are similar to those used in traditional trucks and busses (not diesel/electric hybrid type drive).

In most passenger cars this allows the pinion to be offset to the bottom of the crown wheel.

This provides for longer tooth contact and allows the shaft that drives the pinion to be lowered, reducing the "hump" intrusion in the passenger compartment floor.