Ionization chamber

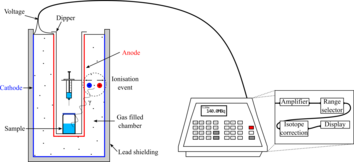

[1] It uses the discrete charges created by each interaction between the incident radiation and the gas to produce an output in the form of a small direct current.

They are widely used in the nuclear power industry, research labs, fire detection, radiation protection, and environmental monitoring.

This generates an ionization current which is measured by an electrometer circuit in the region of femtoamperes to picoamperes, depending on the chamber design, and is proportional to the radiation dose.

This is in distinction to the Geiger–Müller tube or the proportional counter whereby secondary electrons, and ultimately multiple avalanches, greatly amplify the original ionisation charges to produce measurable pulses.

These chambers are normally cylindrical and operate at atmospheric pressure, but to prevent ingress of moisture a filter containing a desiccant is installed in the vent line.

These chambers often have an end window made of material thin enough, such as mylar, so that beta particles can enter the gas volume.

Vented chambers are susceptible to small changes in efficiency with air pressure [2] and correction factors can be applied for very accurate measurement applications.

To improve detection efficiency, they are filled with a noble gas because the highly electronegative oxygen in air easily captures free electrons, forming negative ions.

They are particularly preferred for high dose rate measurements and for gamma radiation they give good accuracy for energies above 50-100 keV.

Some hand held instruments generate audible clicks similar to that produced by a G-M counter to assist operators, who use the audio feedback in radiation survey and contamination checks.

For industrial process measurements and interlocks with sustained high radiation levels, the ion chamber is the preferred detector.

[6] For industrial applications with remote electronics, the ion chamber is housed in a separate enclosure which provides mechanical protection and contains a desiccant to remove moisture which could affect the termination resistance.

In installations where the chamber is a long distance from the measuring electronics, readings can be affected by external electromagnetic radiation acting on the cable.

To overcome this a local converter module is often used to translate the very low ion chamber currents to a pulse train or data signal related to the incident radiation.

They find wide use in situations where a constant high dose rate is being measured as they have a greater operating lifetime than standard Geiger–Müller tubes, which suffer from gas break down and are generally limited to a life of about 1011 count events.

Comparison of the ion currents in the two chambers allows compensation for changes due to air pressure, temperature, or the ageing of the source.

[7] In medical physics and radiotherapy, ionization chambers are used to ensure that the dose delivered from a therapy unit[8] or radiopharmaceutical is what is intended.

[4][10] In the United Kingdom the HSE has issued a user guide on selecting the correct radiation measurement instrument for the particular application concerned.