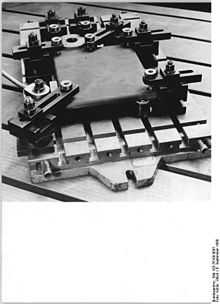

Jig (tool)

A jig's primary purpose is to provide repeatability, accuracy, and interchangeability in the manufacturing of products.

Since the advent of automation and computer numerical controlled (CNC) machines, jigs are often not required because the tool path is digitally programmed and stored in memory.

A drill jig is a type of jig that expedites repetitive hole center location on multiple interchangeable parts by acting as a template to guide the twist drill or other boring device into the precise location of each intended hole center.

In metalworking practice, typically a hardened drill bushing lines each hole on the jig plate to keep the tool from damaging the jig.

Since the widespread penetration of the manufacturing industry by CNC machine tools, in which servo controls are capable of moving the tool to the correct location automatically, the need for drill jigs (and for the jobs of the drill press operators who used them) is much less than it used to be.