Malting

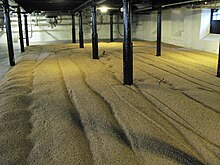

Large mechanical turners, e.g., Saladin boxes, keep the much thicker bed loose with higher productivity and better energy efficiency.

It is taken in from the field and cleaned (dressed), and dried if necessary, to ensure the grain remains in the best condition to produce good malt.

It is tested to check for suitability for malting and to prevent dead or unfit grain from entering the process.

Typical quality checks include: Barley received at the malt house with moisture of more than 13% must be dried before it can be safely stored without loss of germinative capacity.

High temperatures or over-drying will damage or kill the barley embryos and the grain will not germinate after steeping.

The dry barley can safely be stored for up to 18 months without fungal growth or loss of grain vigour.

Magnets are used to remove ferrous metals from the grain, in turn reducing the possibility of sparks, which could lead to a dust explosion.

Rotating and shaking sieves are used to remove unwanted foreign matter either larger (straw and un-threshed ears) or smaller (sand and thin corns) than the normal barley grain.

A typical silo will store between 5,000 and 20,000 tons of clean dry barley ready for malting.

The wet process begins with steeping to get germination started and ends with kilning which removes the moisture and produces a stable final product.

Other advantages of the rousing are to get good mixing, to loosen dirt and to even out hydrostatic pressures at the bottom of the steep vessels.

Fans are run to supply fresh air to replenish oxygen and to remove excess carbon dioxide produced by grain respiration.

[4] The enzymes produced during germination are needed to break down the starch for the brewer or distiller during the mashing process.