Nanoparticle deposition

Bare nanoparticles tend to stabilize themselves either by sorption of molecules from the surroundings or by lowering the surface area through coagulation and agglomeration.

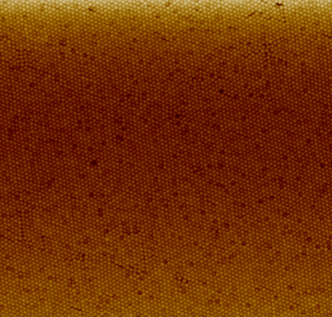

After compressing the particles to the desired packing density, they are transferred on a solid substrate using vertical (Langmuir-Blodgett) or horizontal (Langmuir-Schaefer) dipping to create a monolayer coating.

Controlled multilayer coatings can be made repeating the dipping procedure multiple times.

[2] The benefits of the Langmuir-Blodgett method include a firm control over the packing density and the layer thickness achieved that have been shown to be better than with other methods,[3] the ability to use different shapes and materials of substrates and particles and the possibility to characterize the particle layer during deposition for example a Brewster Angle Microscope.

[4] They are useful tools especially in creating self-assembled layers and films where the packing density isn't critical.