Rotor (electric)

Its rotation is due to the interaction between the windings and magnetic fields which produces a torque around the rotor's axis.

Development quickly included more useful applications such as Moritz Hermann Jacobi's motor that could lift 10 to 12 pounds with a speed of one foot per second, about 15 watts of mechanical power in 1834.

In 1835, Francis Watkins describes an electrical "toy" he created; he is generally regarded as one of the first to understand the interchangeability of motor and generator.

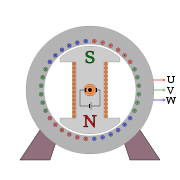

Induction (asynchronous) motors, generators and alternators (synchronous) have an electromagnetic system consisting of a stator and rotor.

The wound rotor is a cylindrical core made of steel lamination with slots to hold the wires for its 3-phase windings which are evenly spaced at 120 electrical degrees apart and connected in a 'Y' configuration.

[5] Brushes on the slip rings allow for external three-phase resistors to be connected in series to the rotor windings for providing speed control.

[6] The external resistances become a part of the rotor circuit to produce a large torque when starting the motor.

In a three-phase induction machine, alternating current supplied to the stator windings energizes it to create a rotating magnetic flux.

[5] The action of the rotating flux and the current produces a force that generates a torque to start the motor.

[12] The magnetic component of the rotor is made from steel laminations to aid stamping conductor slots to specific shapes and sizes.