Programmable logic controller

[1] They can be designed for many arrangements of digital and analog I/O, extended temperature ranges, immunity to electrical noise, and resistance to vibration and impact.

PLCs were first developed in the automobile manufacturing industry to provide flexible, rugged and easily programmable controllers to replace hard-wired relay logic systems.

These early computers were unreliable[5] and required specialist programmers and strict control of working conditions, such as temperature, cleanliness, and power quality.

[7][8] In 1968, GM Hydramatic, the automatic transmission division of General Motors, issued a request for proposals for an electronic replacement for hard-wired relay systems based on a white paper written by engineer Edward R. Clark.

[9][10] Bedford Associates started a company dedicated to developing, manufacturing, selling, and servicing this new product, which they named Modicon (standing for modular digital controller).

A single box (also called a brick) is a small programmable controller that fits all units and interfaces into one compact casing, although, typically, additional expansion modules for inputs and outputs are available.

Either a special high-speed serial I/O link or comparable communication method is used so that racks can be distributed away from the processor, reducing the wiring costs for large plants.

These are typically interpreted as integer values with various ranges of accuracy depending on the device and the number of bits available to store the data.

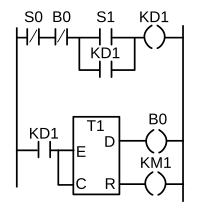

[26] As of 2015,[update] the majority of PLC systems adhere to the IEC 61131-3 standard that defines 2 textual programming languages: Structured Text (similar to Pascal) and Instruction List; as well as 3 graphical languages: ladder logic, function block diagram and sequential function chart.

In addition to being able to program PLCs in multiple languages, they provide common features like hardware diagnostics and maintenance, software debugging, and offline simulation.

The main difference from most other computing devices is that PLCs are intended for and therefore tolerant of more severe conditions (such as dust, moisture, heat, cold), while offering extensive input/output (I/O) to connect the PLC to sensors and actuators.

PLC input can include simple digital elements such as limit switches, analog variables from process sensors (such as temperature and pressure), and more complex data such as that from positioning or machine vision systems.

The data handling, storage, processing power, and communication capabilities of some modern PLCs are approximately equivalent to desktop computers.

PLC-like programming combined with remote I/O hardware, allows a general-purpose desktop computer to overlap some PLCs in certain applications.

Operating systems such as Windows do not lend themselves to deterministic logic execution, with the result that the controller may not always respond to changes of input status with the consistency in timing expected from PLCs.

Unlike physical relays, there is usually no limit to the number of times an input, output or internal coil can be referenced in a PLC program.

PLCs use built-in ports, such as USB, Ethernet, RS-232, RS-485, or RS-422 to communicate with external devices (sensors, actuators) and systems (programming software, SCADA, user interface).

It typically takes a time span of tens of milliseconds for the processor to evaluate all the instructions and update the status of all outputs.

This allows even a relatively slow PLC to still interpret the counted values to control a machine, as the accumulation of pulses is done by a dedicated module that is unaffected by the speed of program execution.

[39] In February 2021, Rockwell Automation publicly disclosed a critical vulnerability affecting its Logix controllers family.

[40][41] Safety PLCs can be either a standalone device or a safety-rated hardware and functionality added to existing controller architectures (Allen-Bradley GuardLogix, Siemens F-series, etc.).

This is due to the lower cost of the components, which can be optimally chosen instead of a "generic" solution, and where the non-recurring engineering charges are spread over thousands or millions of units.

They are similar to traditional PLCs, but their small size allows developers to design them into custom printed circuit boards like a microcontroller, without computer programming knowledge, but with a language that is easy to use, modify and maintain.

However, some specialty vehicles such as transit buses economically use PLCs instead of custom-designed controls, because the volumes are low and the development cost would be uneconomical.

[42] Very complex process control, such as those used in the chemical industry, may require algorithms and performance beyond the capability of even high-performance PLCs.

Single-board computers using semi-customized or fully proprietary hardware may be chosen for very demanding control applications where the high development and maintenance cost can be supported.

"Soft PLCs" running on desktop-type computers can interface with industrial I/O hardware while executing programs within a version of commercial operating systems adapted for process control needs.

These small devices are typically made in a common physical size and shape by several manufacturers and branded by the makers of larger PLCs to fill their low-end product range.

Most such devices include a tiny postage stamp-sized LCD screen for viewing simplified ladder logic (only a very small portion of the program being visible at a given time) and status of I/O points, and typically these screens are accompanied by a 4-way rocker push-button plus four more separate push-buttons, similar to the key buttons on a VCR remote control, and used to navigate and edit the logic.

Most have an RS-232 or RS-485 port for connecting to a PC so that programmers can use user-friendly software for programming instead of the small LCD and push-button set for this purpose.