Power supply

Examples of the latter include power supplies found in desktop computers and consumer electronics devices.

Some power supplies have other types of inputs and outputs as well, for functions such as external monitoring and control.

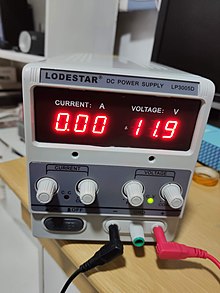

A bench power supply is a stand-alone desktop unit used in applications such as circuit test and development.

Open frame power supplies have only a partial mechanical enclosure, sometimes consisting of only a mounting base; these are typically built into machinery or other equipment.

These are popular in consumer electronics because of their safety; the hazardous 120 or 240 volt main current is transformed down to a safer voltage before it enters the appliance body.

The electric load's tolerance of ripple dictates the minimum amount of filtering that must be provided by the power supply.

In a switched-mode power supply (SMPS), the AC mains input is directly rectified and then filtered to obtain a DC voltage.

After the inductor or transformer secondary, the high frequency AC is rectified and filtered to produce the DC output voltage.

If the SMPS uses an adequately insulated high-frequency transformer, the output will be electrically isolated from the mains; this feature is often essential for safety.

SMPSs often include safety features such as current limiting or a crowbar circuit to help protect the device and the user from harm.

[1] In the event that an abnormal high-current power draw is detected, the switched-mode supply can assume this is a direct short and will shut itself down before damage is done.

In a no-load condition the frequency of the power slicing circuit increases to great speed, causing the isolated transformer to act as a Tesla coil, causing damage due to the resulting very high voltage power spikes.

In simple switch-mode power supplies, the input stage may distort the line voltage waveform, which can adversely affect other loads (and result in poor power quality for other utility customers), and cause unnecessary heating in wires and distribution equipment.

Furthermore, customers incur higher electric bills when operating lower power factor loads.

Consequently, to avoid exposing people and equipment from hazardous high voltage, anything connected to the power supply must be reliably insulated.

Other kinds of AC power supplies are designed to provide a nearly constant current, and output voltage may vary depending on impedance of the load.

A circuit may be designed with a voltage multiplier topology to directly step-up AC power; formerly, such an application was a vacuum tube AC/DC receiver.

AC power Supplies can also be used to change the frequency as well as the voltage, they are often used by manufacturers to check the suitability of their products for use in other countries.

A programmable power supply (PPS) is one that allows remote control of its operation through an analog input or digital interface such as RS-232 or GPIB.

Controlled properties may include voltage, current, and in the case of AC output power supplies, frequency.

They are used in a wide variety of applications, including automated equipment testing, crystal growth monitoring, semiconductor fabrication, and x-ray generators.

A special output connector is used that prevents arcing, insulation breakdown and accidental human contact.

Some high-voltage power supplies provide an analog input or digital communication interface that can be used to control the output voltage.

High-voltage power supplies are commonly used to accelerate and manipulate electron and ion beams in equipment such as x-ray generators, electron microscopes, and focused ion beam columns, and in a variety of other applications, including electrophoresis and electrostatics.

High-voltage power supplies typically apply the bulk of their input energy to a power inverter, which in turn drives a voltage multiplier or a high turns ratio, high-voltage transformer, or both (usually a transformer followed by a multiplier) to produce high voltage.

A bipolar power supply operates in all four quadrants of the voltage/current Cartesian plane, meaning that it will generate positive and negative voltages and currents as required to maintain regulation.

Common conduction cooling methods include heat sinks, cold plates, and thermal compounds.

This effectively disconnects the power supply from its load, and the equipment stops working until the problem that caused the overload is identified and the fuse is replaced.

Both commercial and military avionic systems require either a DC-DC or AC/DC power supply to convert energy into usable voltage.

This refers to conveyors, assembly lines, bar code readers, cameras, motors, pumps, semi-fabricated manufacturing and more.