Pencil

Pencils create marks by physical abrasion, leaving a trail of solid core material that adheres to a sheet of paper or other surface.

Coloured pencils are sometimes used by teachers or editors to correct submitted texts, but are typically regarded as art supplies, especially those with cores made from wax-based binders that tend to smear when erasers are applied to them.

Grease pencils have a softer, oily core that can leave marks on smooth surfaces such as glass or porcelain.

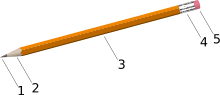

The most common pencil casing is thin wood, usually hexagonal in section, but sometimes cylindrical or triangular, permanently bonded to the core.

To use the pencil, the casing must be carved or peeled off to expose the working end of the core as a sharp point.

As a technique for drawing, the closest predecessor to the pencil was silverpoint or leadpoint until, in 1565 (some sources say as early as 1500), a large deposit of graphite was discovered on the approach to Grey Knotts from the hamlet of Seathwaite in Borrowdale parish, Cumbria, England.

[12][13][14][15][16] The words for pencil in German (Bleistift), Irish (peann luaidhe), Arabic (قلم رصاص qalam raṣāṣ), and some other languages literally mean lead pen.

The value of graphite would soon be realised to be enormous, mainly because it could be used to line the moulds for cannonballs; the mines were taken over by the Crown and were guarded.

England would enjoy a monopoly on the production of pencils until a method of reconstituting the graphite powder was found in 1662 in Germany.

However, the distinctively square English pencils continued to be made with sticks cut from natural graphite into the 1860s.

[18] Around 1560,[19] an Italian couple named Simonio and Lyndiana Bernacotti made what are likely the first blueprints for the modern, wood-encased carpentry pencil.

[21][22][23] English and German pencils were not available to the French during the Napoleonic Wars; France, under naval blockade imposed by Great Britain, was unable to import the pure graphite sticks from the British Grey Knotts mines – the only known source in the world.

In 1795, Nicolas-Jacques Conté discovered a method of mixing powdered graphite with clay and forming the mixture into rods that were then fired in a kiln.

This method of manufacture, which had been earlier discovered by the Austrian Joseph Hardtmuth, the founder of the Koh-I-Noor in 1790, remains in use.

[26][better source needed] William Munroe, a cabinetmaker in Concord, Massachusetts, made the first American wood pencils in 1812.

According to Henry Petroski, transcendentalist philosopher Henry David Thoreau discovered how to make a good pencil out of inferior graphite using clay as the binder; this invention was prompted by his father's pencil factory in Concord, which employed graphite found in New Hampshire in 1821 by Charles Dunbar.

[27] Joseph Dixon, an inventor and entrepreneur involved with the Tantiusques graphite mine in Sturbridge, Massachusetts, developed a means to mass-produce pencils.

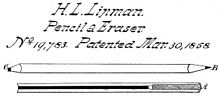

[35] In 1862, Lipman sold his patent to Joseph Reckendorfer for $100,000, who went on to sue pencil manufacturer Faber-Castell for infringement.

Carbon pencils are generally made of a mixture of clay and lamp black, but are sometimes blended with charcoal or graphite depending on the darkness and manufacturer.

They produce a fuller black than graphite pencils, are smoother than charcoal, and have minimal dust and smudging.

[39] Grease pencils can write on virtually any surface (including glass, plastic, metal and photographs).

Until the middle of the 20th century the paint used for the outer coating could contain high concentrations of lead, and this could be ingested when the pencil was sucked or chewed.

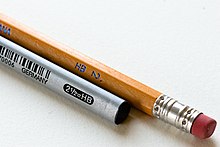

[56][additional citation(s) needed] The lead of the pencil is a mix of finely ground graphite and clay powders.

Before the two substances are mixed, they are separately cleaned of foreign matter and dried in a manner that creates large square cakes.

The mixture is then shaped into long spaghetti-like strings, straightened, dried, cut, and then tempered in a kiln.

The resulting strings are dipped in oil or molten wax, which seeps into the tiny holes of the material and allows for the smooth writing ability of the pencil.

Another grooved plank is glued on top, and the whole assembly is then cut into individual pencils, which are then varnished or painted.

A higher amount of clay added to the pencil makes it harder, leaving lighter marks.

[e] According to Henry Petroski,[76] this tradition began in 1890 when the L. & C. Hardtmuth Company of Austria-Hungary introduced their Koh-I-Noor brand, named after the famous diamond.

As well as simply being distinctive, the colour may have been inspired by the Austro-Hungarian flag; it was also suggestive of the Orient at a time when the best-quality graphite came from Siberia.