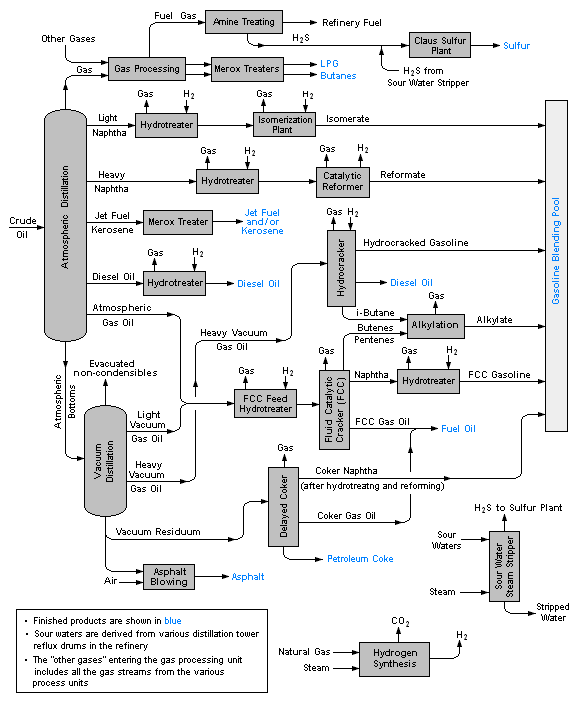

Refinery

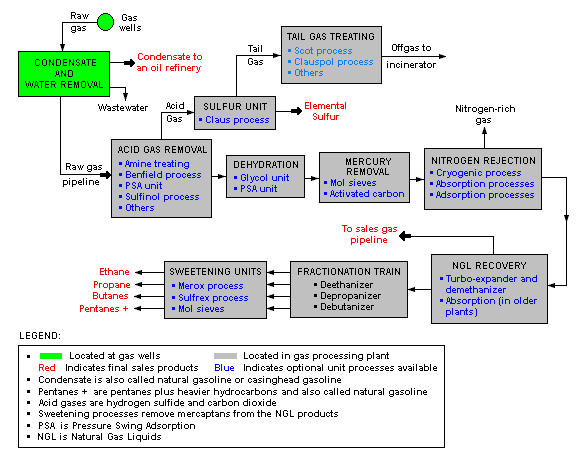

[2][3][4][5][6] The image below is a schematic block flow diagram of a typical natural gas processing plant.

The juices (containing 10-15 percent sucrose) are collected and mixed with lime to adjust pH to 7, prevent decay into glucose and fructose, and precipitate impurities.

The lime and other suspended solids are settled out, and the clarified juice is concentrated in a multiple-effect evaporator to make a syrup with about 60 weight percent sucrose.

The fibrous solids, called bagasse, remaining after the crushing of the shredded sugarcane are burned for fuel which helps a sugar mill to become self-sufficient in energy.

Any excess bagasse can be used for animal feed, to produce paper, or burned to generate electricity for the local power grid.