Repulsion motor

In repulsion motors the stator windings are connected directly to the AC power supply and the rotor is connected to a commutator and brush assembly, similar to that of a direct current (DC) motor.

The rotor winding is connected to a commutator which is in contact with a short-circuited pair of brushes which can be moved to change their angular position relative to an imaginary line drawn through the axis of the stator.

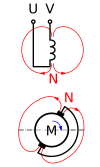

The motor can be started, stopped and reversed, and the speed can be varied, simply by changing the angular position of the brushes.

Repulsion motors can be used at higher voltages because the rotor circuit is not electrically connected to the supply.

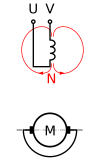

When alternating current is supplied to the field (stator) winding, it induces an electromotive force (emf) in the armature.

The direction of rotation is determined by the position of the brushes with respect to the magnetic field of the stator.

The starting torque of a repulsion motor is determined by the angle of brush shift from the main magnetic axis.

It is likely that the different types were developed to match the torque/speed characteristics of the motor as closely as possible to the service it was required to provide.

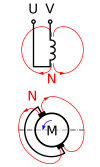

The Deri motor is similar to the Elihu Thomson type but has two pairs of short-circuited brushes—one fixed and one moveable.

They started as repulsion motors, but once they were running at a sizable fraction of full speed, the brushes were lifted mechanically and all commutator bars were short-circuited together to create the equivalent of a squirrel-cage induction motor.