Rework (electronics)

Mass processing techniques are not applicable to single device repair or replacement, and specialized manual techniques by expert personnel using appropriate equipment are required to replace defective components; area array packages such as ball grid array (BGA) devices particularly require expertise and appropriate tools.

[2] For electronics, defects may include: The rework may involve several components, which must be worked on one by one without damage to surrounding parts or the PCB itself.

Imperfect connections of devices which are not themselves faulty, which work for a time and then fail, often triggered by thermal expansion and contraction at operating temperature, are not infrequent.

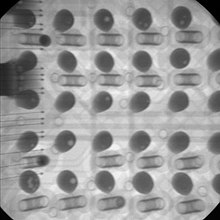

Assemblies which fail because of bad BGA connections can be repaired either by reflowing, or by removing the device and cleaning it of solder, reballing, and replacing.

Reflowing as a rework technique, similar to the manufacturing process of reflow soldering, involves dismantling the equipment to remove the faulty circuit board, pre-heating the whole board in an oven, heating the non-functioning component further to melt the solder, then cooling, following a carefully determined thermal profile, and reassembling, a process which is hoped will repair the bad connection without the need to remove and replace the component.

For typical devices (PlayStation 3 and Xbox 360) one repair company estimates that the process, if there are no unexpected problems, takes about 80 minutes.

[6] While such methods can cure some problems, the outcome is likely to be less successful than is possible with accurate thermal profiling achieved by an experienced technician using professional equipment.

Manufacturer and service providers of communications-technologies, entertainment- and consumer-devices, industrial commodities, automobiles, medical technology, aerospace and other high power electronics rework when necessary.