Rolling contact fatigue

[2][3] The RCF process begins with cyclic loading of the material, which results in fatigue damage that can be observed in crack-like flaws, like white etching cracks.

[2] Over time, the repeated passing of wheels with high contact pressures can cause the formation of crack-like flaws that becomes small cracks.

[2] These cracks can grow and sometimes join, leading to either surface spalling or rail break, which can cause serious accidents, including derailments.

[2][4] RCF is a major concern for railways worldwide and can take various forms depending on the location of the crack and its appearance.

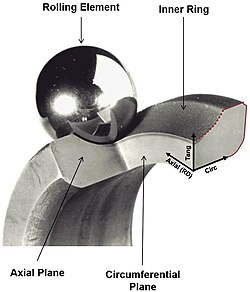

[2] It is also a significant cause of failure in components subjected to rolling or rolling/sliding contacts, such as rolling-contact bearings, gears, and cam/tappet arrangements.

[5] The alternating stress field in RCF can lead to material removal, varying from micro- and macro-pitting in conventional bearing steels to delamination in hybrid ceramics and overlay coatings.

Here are some of the methods used: Triple disc rolling contact fatigue (RCF) Rig is a specialised testing apparatus used in the field of tribology and materials science to evaluate the fatigue resistance and durability of materials subjected to rolling contact.

[10][11] PCS Instruments Micro-pitting Rig (MPR) is a specialised testing instrument used in the field of tribology and mechanical engineering to study micro-pitting, a type of surface damage that occurs in lubricated rolling and sliding contact systems.