Sailcloth

[1] Doek is Dutch for cloth, which evolved into the English word "duck" in reference to sail canvas.

[3][4] Some examples of pandan mat sails were so finely woven that they were compared to "coarse linen" by the Spanish and "dressed sheepskin" by the Dutch.

The technology of pandan mat sails were also introduced to non-Austronesian peoples via contact, like to the Yolngu of Australia.

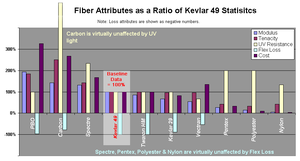

According to Mahr, there are six key factors in evaluating a fiber for suitability in weaving a sail-cloth:[17] There is no perfect solution since in most cases the increase of one attribute generally results in the decreased attractiveness of another.

Nylon is used in spinnakers because of its light weight, high tensile strength, superior abrasion resistance and flexibility.

Nylon is more susceptible to UV and chemical degradation than polyesters and its physical properties can change due to moisture absorption.

PET has been replaced by stronger fibers for most serious racing applications, but remains the most popular sail cloth due to lower price and high durability.

Dacron is the brand name of Dupont’s Type 52 high modulus fiber made specifically for sailcloth.

It is stronger, has a higher strength to weight ratio than steel, and has a modulus that is five times greater than PET, and about twice as high as PEN.

Minimal flogging and careful handling can greatly extend the life of a Kevlar sail.

Twaron is an aramid, which is produced in The Netherlands by Teijin, is chemically and physically similar to DuPont’s Kevlar.

Twaron HM (High modulus) has similar stretch properties to Kevlar 49, greater tensile strength and better UV resistance.

Equivalent to Spectra, Dyneema is an extremely strong fiber produced by the Dutch company DSM.

It is often used by European sailcloth manufacturers, is available in a wider variety of yarn sizes than Spectra, and is growing in popularity.

It has similar properties to Spectra including superior resistance to flex fatigue and UV degradation but also exhibits creep.

PBO (Poly (p-phenylene-2, 6-benzobisoxazole)) is liquid crystal polymer developed by Japan-based Toyobo under the trade name Zylon.

Vectran is a polyester-based high performance LCP (liquid crystal polymer) produced by Ticona.

Variants can balance along a continuum from brittle with no-stretch to extreme durability/flexibility with only slightly more stretch than aramid sails.

As load is applied the yarns attempt to straighten out, this results in the fabric stretching, commonly referred to as "crimp".

However, PEN film is rarely used in standard sailcloth styles because it shrinks more rapidly than PET, is less resistant to abuse, and reduces the working life of the sail.

Strands are combined from fibers; these are frequently narrow flat bands or ribbons of high strength material.

Scrim is a loose weave or lattice of strands, typically bonded where they cross to maintain the grid pattern.

Thus load-bearing members are laid straight, which maximizes the high modulus of the fibers, where a woven material will have some inherent stretch to the weave.

The drawbacks are: film is not as abrasion or flex resistant as a weave, it does not protect the structural fibers from UV rays.