Shear modulus

Its dimensional form is M1L−1T−2, replacing force by mass times acceleration.

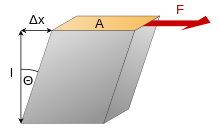

All of them arise in the generalized Hooke's law: These moduli are not independent, and for isotropic materials they are connected via the equations[9] The shear modulus is concerned with the deformation of a solid when it experiences a force parallel to one of its surfaces while its opposite face experiences an opposing force (such as friction).

In the case of an object shaped like a rectangular prism, it will deform into a parallelepiped.

Anisotropic materials such as wood, paper and also essentially all single crystals exhibit differing material response to stress or strain when tested in different directions.

In this case, one may need to use the full tensor-expression of the elastic constants, rather than a single scalar value.

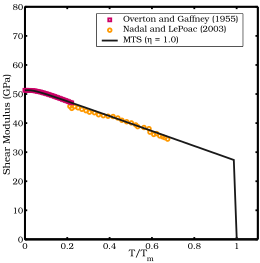

Correlations between the melting temperature, vacancy formation energy, and the shear modulus have been observed in many metals.

[13] Several models exist that attempt to predict the shear modulus of metals (and possibly that of alloys).

The empirical temperature dependence of the shear modulus in the SCG model is replaced with an equation based on Lindemann melting theory.

The NP shear modulus model has the form: where and μ0 is the shear modulus at absolute zero and ambient pressure, ζ is an area, m is the atomic mass, and f is the Lindemann constant.