Slag (welding)

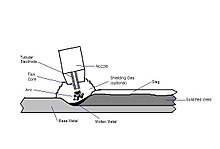

Slag is the solidified remaining flux after the weld area cools.

The gases produced push the atmospheric gas back, preventing oxidation (and reactions with nitrogen).

The flux cover also helps thermally insulate the weld and reduce the cooling rate.

Inclusions may be visible on the surface after cleaning, or may be completely contained within the metal, in that case they can only be detected on X-rays of the weld, requiring grinding or drilling to remove (followed by re-welding that section).

Manual tools may include a welding or chipping hammer, which has a pointed tip on one end to break up large chunks of slag efficiently, or wire brushes.