Spark arrestor

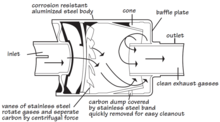

One popular design was the Radley–Hunter spark arrester, which used a spiral-shaped cone to separate embers from the exhaust flow by centrifugal force.

[2] Their experiments demonstrated that hot particulate matter larger than 0.023 inches (0.584 mm) in diameter was capable of igniting wildland fuels.

Vehicles without properly functioning spark arresters have been suspected of starting numerous wildfires, including the devastating track fire near Raton, New Mexico in June 2011.

[4] Today, spark arresters can be found as OEM or aftermarket components on many types of equipment, such as large agricultural machines, off highway vehicles (OHVs), and small engines (chainsaws, string trimmers, leaf blowers, etc.).

Spark arresters are also fitted to the top of a flue (or a chimney pot) to prevent floating embers from a fire (particularly one burning wood) setting light to a flammable roofing surface (shingle, thatch, or bitumen-felt) or falling onto combustible material on the ground.

Such a spark arrester typically consists of a double layer of metal mesh, which catches the ember and allows the flue gas to escape.

During periods of extreme fire danger, land managers may prevent the use of all motorized equipment, even if a properly functioning spark arrester is installed.

Certification testing of spark arresters is performed by the USDA Forest Service Technology and Development Center in San Dimas, CA.