Loudspeaker enclosure

Enclosures may range in design from simple, homemade DIY rectangular particleboard boxes to very complex, expensive computer-designed hi-fi cabinets that incorporate composite materials, internal baffles, horns, bass reflex ports and acoustic insulation.

Because the forward- and rearward-generated sounds are out of phase with each other, any interaction between the two in the listening space creates a distortion of the original signal as it was intended to be reproduced.

Enclosures designed for use in PA systems, sound reinforcement systems and for use by electric musical instrument players (e.g., bass amp cabinets) have a number of features to make them easier to transport, such as carrying handles on the top or sides, metal or plastic corner protectors, and metal grilles to protect the speakers.

Speaker enclosures designed for use in a home or recording studio typically do not have handles or corner protectors, although they do still usually have a cloth or mesh cover to protect the woofer and tweeter.

An open baffle loudspeaker is an approximation of this, since the driver is mounted on a panel, with dimensions comparable to the longest wavelength to be reproduced.

The forward- and rearward-generated sounds of a speaker driver appear out of phase from each other because they are generated through the opposite motion of the diaphragm and because they travel different paths before converging at the listener's position.

A speaker driver mounted on a finite baffle will display a physical phenomenon known as interference, which can result in perceivable frequency-dependent sound attenuation.

Enclosures can have a significant effect beyond what was intended, with panel resonances, diffraction from cabinet edges[6][7] and standing wave energy from internal reflection/reinforcement modes being among the possible problems.

A comprehensive study of the effect of cabinet configuration on the sound distribution pattern and overall response-frequency characteristics of loudspeakers was undertaken by Harry F.

[6][7] It involved a very wide number of different enclosure shapes, and it showed that curved loudspeaker baffles reduce some response deviations due to sound wave diffraction.

In a closed-box loudspeaker, the air inside the box acts as a spring, returning the cone to the zero position in the absence of a signal.

A significant increase in the effective volume of a closed-box loudspeaker can be achieved by a filling of fibrous material, typically fiberglass, bonded acetate fiber (BAF) or long-fiber wool.

The effective volume increase can be as much as 40% and is due primarily to a reduction in the speed of sound propagation through the filler material as compared to air.

A variation on the open baffle approach is to mount the loudspeaker driver in a very large sealed enclosure, providing minimal air spring restoring force to the cone.

This is often the case with exotic rotary woofer installations, as they are intended to go to frequencies lower than 20 Hz and displace large volumes of air.

The term is often and erroneously used of sealed enclosures which cannot exhibit infinite-baffle behavior unless their internal volume is much greater than the Vas Thiele/Small of the drive unit AND the front baffle dimensions are ideally several wavelengths of the lowest output frequency.

The voltage sensitivity above the tuning frequency remains a function of the driver, and not of the cabinet design.The isobaric loudspeaker configuration was first introduced by Harry F. Olson in the early 1950s, and refers to systems in which two or more identical woofers (bass drivers) operate simultaneously, with a common body of enclosed air adjoining one side of each diaphragm.

In practical applications, they are most often used to improve low-end frequency response without increasing cabinet size, though at the expense of cost and weight.

These enclosures are sensitive to small variations in driver characteristics and require special quality control concern for uniform performance across a production run.

In theory, such designs are variations of the bass reflex type, but with the advantage of avoiding a relatively small port or tube through which air moves, sometimes noisily.

A resistive mat is placed in front of or directly behind the loudspeaker driver (usually mounted on the rear deck of the car in order to use the trunk as an enclosure).

This increases mechanical damping, and the resulting decrease in the impedance magnitude at resonance is generally the desired effect, though there is no perceived or objective benefit to this.

This is reinforced by the purveyors of AP membranes; they are often sold with an electronic processor which, via equalization, restores the bass output lost through the mechanical damping.

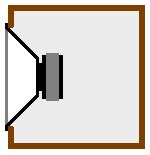

A dipole enclosure in its simplest form is a driver located on a flat baffle panel, similar to older open back cabinet designs.

A dipole enclosure has a figure-of-eight radiation pattern, which means that there is a reduction in sound pressure, or loudness, at the sides as compared to the front and rear.

Various speaker manufacturers have produced folded low-frequency horns which are much smaller (e.g., Altec Lansing, JBL, Klipsch, Lowther, Tannoy) and actually fit in practical rooms.

Depending on implementation, this design offers an improvement in transient response as each of the drivers is aligned in phase and time and exits the same horn mouth.

Transmission lines tend to be larger than ported enclosures of approximately comparable performance, due to the size and length of the guide that is required (typically 1/4 the longest wavelength of interest).

But it is the inherent resonance (typically at 1/4 wavelength) that can enhance the bass response in this type of enclosure, albeit with less absorbent stuffing.

The tapering tube can be coiled for lower frequency driver enclosures to reduce the dimensions of the speaker system, resulting in a seashell like appearance.