Transmission line loudspeaker

Used correctly, such a design ensures that undesired resonances and energies, which would otherwise cause undesirable auditory effects, are instead selectively absorbed or reduced ("damped") due to the effects of the duct, or alternatively only emerge from the open end in phase with the sound radiated from the front of the driver, enhancing the output level ("sensitivity") at low frequencies.

The transmission line acts as an acoustic waveguide, and the padding both reduces reflection and resonance, and also slows the speed of sound within the cabinet to allow for better tuning.

Transmission line loudspeakers designs are more complex to implement, making mass production difficult, but their advantages have led to commercial success for a number of manufacturers such as IMF, TDL, and PMC.

As a rule, transmission line speakers tend to have exceptionally high fidelity low frequency response far below that of a typical speaker or subwoofer, reaching into the infrasonic range (British company TDL's studio monitor range from the 1990s quoted their frequency responses as starting from as low as 17 Hz depending upon model with a sensitivity of 87 dB for 1 W @ 1 meter), without the need for a separate enclosure or driver.

[1][2] Acoustically, TL speakers roll off more slowly (less steeply) at low frequencies, and they are thought to provide better driver control than standard vented-box cabinet designs,[3] are less sensitive to positioning, and tend to create a very spacious soundstage.

Modern TL speakers were described in a 2000 review as "match[ing] reflex cabinet designs in every respect, but with an extra octave of bass, lower LF distortion and a frequency balance which is more independent of listening level".

[The TL design] also produces higher SPL [sensitivity or loudness] and lower bass extension than ported or sealed box of similar size.

There are many ways in which the duct can be folded, and the line is often tapered in cross section to avoid parallel internal surfaces that encourage standing waves.

Depending upon the drive unit, and quantity and various physical properties of absorbent material, the amount of taper will be adjusted during the design process to tune the duct to remove irregularities in its response.

The inside faces of the duct or line, are treated with an absorbent material to provide the correct termination with frequency to load the drive unit as a TL.

Essentially, the goal of the transmission line is to minimize acoustical or mechanical impedance at frequencies corresponding to the fundamental free-air resonance of the bass driver.

This taper serves to dampen the buildup of standing waves within the line, which can create sharp nulls in response at the terminus output at even multiples of the driver's Fs.

Fried quoted in 2002, a listening test performed and reported in December 2000's Hi-Fi News (as he believed) in which a high-quality recording was obtained using reputable but non-time-coherent loudspeakers and this recording was then time phase corrected; an expert listening panel "voted unanimously for the superior realism and accuracy of the time corrected output" for high quality sound reproduction.

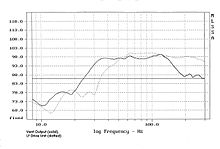

For example, the large IMF TLS80 MkII from 1977 also had an anomaly, but this time at the lower frequency of about 140 Hz, consisting of an almost one-octave-wide deleterious 2-dB dip in the on-axis response.

A transmission line speaker employs, essentially, two distinct forms of bass loading, which historically and confusingly have been amalgamated in the TL description.

Measurements indicate that the upper bass is only partially absorbed by the line, making a clean and neutral response somewhat difficult if not impossible to achieve.

The main disadvantage of the design is that it is more labor-intensive to create and tune a high quality and consistent transmission line, compared to building a simple vented-box or closed-box enclosure.

[12] A 2010 Hifi Avenue TL speaker review commented that "One thing I have noticed about transmission line designs is that they create a rather big soundstage and seem to handle crescendoes with ease".

Bailey in Wireless World magazine, referencing a production version of an acoustic-line enclosure design from Radford Electronics Ltd.[16] The article postulated that energy from the rear of a driver unit could be essentially absorbed, without damping the cone's motion or superimposing internal reflections and resonance, so Bailey and Radford reasoned that the rear wave could be channelled down a long pipe.

[7] The British pair, along with Hayes' colleague David Brown, agreed to form a UK company to design and manufacture speakers which would be sold by Fried in the United States.

Because the line is operating over several octaves with the drive unit, cone excursion is reduced, providing higher SPLs and lower distortion levels, as compared with bass reflex and infinite baffle loudspeaker enclosure designs.

The complex loading of the bass drive unit demands specific Thiele-Small driver parameters to realise the full benefits of a TL design.

High efficiency bass drivers with extended low frequency ability, are usually designed to be extremely light and flexible, having very compliant suspensions.

High specification acoustic foams, developed by manufacturers such as PMC, with similar characteristics to longhaired wool, provide repeatable results for consistent production.

Filling half the cross section throughout the line's entire length treats the TL as an infinite baffle, basically damping high frequencies and wall-to-wall resonances.

[23] However, from the 21st Century, Martin King and George Augspurger (both separately and referencing each other's works), produced models which show these to be "generally less than optimal" designs which "did a good job of approaching what was possible in their day".

[23] More recently, Andrea Rubino has developed a sophisticated simulation model based on electrical circuit theory and published a series of articles in the Italian electroacoustic journal AUDIOreview.