Spring (device)

A spring is a device consisting of an elastic but largely rigid material (typically metal) bent or molded into a form (especially a coil) that can return into shape after being compressed or extended.

An example of a non-metallic spring is the bow, made traditionally of flexible yew wood, which when drawn stores energy to propel an arrow.

When a conventional spring, without stiffness variability features, is compressed or stretched from its resting position, it exerts an opposing force approximately proportional to its change in length (this approximation breaks down for larger deflections).

An extension or compression spring's rate is expressed in units of force divided by distance, for example or N/m or lbf/in.

A torsion spring's rate is in units of torque divided by angle, such as N·m/rad or ft·lbf/degree.

Small springs can be wound from pre-hardened stock, while larger ones are made from annealed steel and hardened after manufacture.

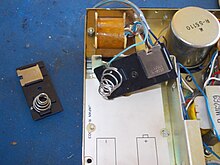

Some non-ferrous metals are also used, including phosphor bronze and titanium for parts requiring corrosion resistance, and low-resistance beryllium copper for springs carrying electric current.

In the Bronze Age more sophisticated spring devices were used, as shown by the spread of tweezers in many cultures.

Ctesibius of Alexandria developed a method for making springs out of an alloy of bronze with an increased proportion of tin, hardened by hammering after it was cast.

On March 8, 1850, John Evans, Founder of John Evans' Sons, Incorporated, opened his business in New Haven, Connecticut, manufacturing flat springs for carriages and other vehicles, as well as the machinery to manufacture the springs.

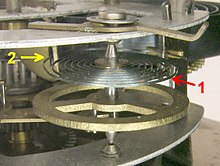

If made with constant pitch (wire thickness), conical springs have a variable rate.

Since acceleration is simply the second derivative of x with respect to time, This is a second order linear differential equation for the displacement

The potential energy U of such a system can be determined through the spring constant k and its displacement x:[14]

[14] The period T, the amount of time for the spring-mass system to complete one full cycle, of such harmonic motion is given by:[16]

[14] The frequency f, the number of oscillations per unit time, of something in simple harmonic motion is found by taking the inverse of the period:[14]

Hooke's law of elasticity states that the extension of an elastic rod (its distended length minus its relaxed length) is linearly proportional to its tension, the force used to stretch it.

This law actually holds only approximately, and only when the deformation (extension or contraction) is small compared to the rod's overall length.

Moreover, for the superelastic materials, the linear relationship between force and displacement is appropriate only in the low-strain region.

Hooke's law is a mathematical consequence of the fact that the potential energy of the rod is a minimum when it has its relaxed length.

Therefore, the force – which is the derivative of energy with respect to displacement – approximates a linear function.

"Length" here is defined as the distance between the axes of the pivots at each end of the spring, regardless of any inelastic portion in-between.

Long-period pendulums enable seismometers to sense the slowest waves from earthquakes.

The LaCoste suspension with zero-length springs is also used in gravimeters because it is very sensitive to changes in gravity.