Timer

They function similarly to a mechanical alarm clock, the energy in the mainspring causes a balance wheel to rotate back and forth.

The simplest and oldest type of mechanical timer is the hourglass - which is also known as "the glass of the hour" - in which a fixed amount of sand drains through a narrow opening from one chamber to another to measure a time interval.

The AC motor is turned at an accurate rate by the alternating current, which power companies carefully regulate.

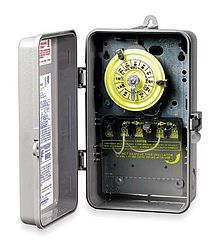

Electromechanical timers survive in these applications because mechanical switch contacts may still be less expensive than the semiconductor devices needed to control powerful lights, motors and heaters.

Programmable electromechanical timers controlled launch sequence events in early rockets and ballistic missiles.

Individual timers are implemented as a simple single-chip computer system, similar to a watch and usually utilizing the same, mass-produced technology.

These are typically digital counters that either increment or decrement at a fixed frequency, which is often configurable, and which interrupt the processor when reaching zero.

An alternative design uses a counter with a sufficiently large word size that it will not reach its overflow limit before the end of life of the system.

This might be used, for example, to measure events or generate pulse-width modulated waveforms to control the speed of motors (using a class D digital electronic amplifier).

Mechanical timers lack the customization that applications support, such as sound volume adjustments for individual needs.