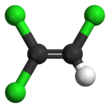

Trichloroethylene

It is a clear, colourless, non-flammable, volatile liquid with a chloroform-like pleasant mild smell[3] and sweet taste.

It was obtained from the action of potassium hydroxide on 1,1,2,2-tetrachloroethane and 1,1,1,2-tetrachloroethane by Auguste Laurent and notated as C4HCl3 (then the atomic weight of carbon was thought to be the half of it really was).

Legislation has forced the replacement of trichloroethylene in many processes in Europe as the chemical was classified as a carcinogen carrying an R45 risk phrase, May cause cancer.

Many degreasing chemical alternatives are being promoted such as Ensolv and Leksol; however, each of these is based on n-propyl bromide which carries an R60 risk phrase of May impair fertility, and would not be a legally acceptable substitute.

Pioneered by Imperial Chemical Industries in Britain, under the trade name "Trilene" (from trichloroethylene) , its development was hailed as an anesthetic revolution.

The –mar suffix indicates study and development at the University of Maryland, e.g., "Fluoromar" for fluroxene and "Vinamar" for ethyl vinyl ether".

These included promotion of cardiac arrhythmias, low volatility and high solubility preventing quick anesthetic induction, reactions with soda lime used in carbon dioxide absorbing systems, prolonged neurologic dysfunction when used with soda lime, and evidence of hepatotoxicity as had been found with chloroform.

Alkali components of carbon dioxide absorbers reacted with trichloroethylene and released dichloroacetylene, a neurotoxin.

First, acetylene was treated with chlorine using a ferric chloride catalyst at 90 °C to produce 1,1,2,2-tetrachloroethane according to the chemical equation: The 1,1,2,2-tetrachloroethane is then dehydrochlorinated to give trichloroethylene.

This can be accomplished either with an aqueous solution of calcium hydroxide: or in the vapor phase by heating it to 300–500 °C on a barium chloride or calcium chloride catalyst: Common impurities in reagent and technical grade TCE are methyl chloroform, carbon tetrachloride, ethylene dichloride, tetrachloroethanes, benzene and phenol.

[24] When trichloroethylene was first widely produced in the 1920s, its major use was to extract vegetable oils from plant materials such as soy, coconut, and palm.

Other uses in the food industry included coffee decaffeination (removal of caffeine) and the preparation of flavoring extracts from hops and spices.

[25][26] The F-1 rocket engine had its LOX dome, gas generator, and thrust chamber fuel jacket flushed with TCE during launch preparations.

TCE was also used in industrial refrigeration applications due to its high heat transfer capabilities and its low-temperature specification.

Since the reactive instability is accentuated by higher temperatures, the search for stabilizing additives was conducted by heating trichloroethylene to its boiling point under a reflux condenser and observing decomposition.

These effects may be mediated by trichloroethylene acting as a positive allosteric modulator of inhibitory GABAA and glycine receptors.

It was noted in the 1940s that TCE reacted with carbon dioxide (CO2) absorbing systems (soda lime) to produce dichloroacetylene by dehydrochlorination and phosgene.

For these reasons as well as problems with hepatotoxicity, TCE lost popularity in North America and Europe to more potent anesthetics such as halothane by the 1960s.

[35] A history of long-term exposure to high concentrations of trichloroethylene is a suspected environmental risk of Parkinson's disease.

With a specific gravity greater than 1 (denser than water), trichloroethylene can be present as a dense non-aqueous phase liquid (DNAPL) if sufficient quantities are spilt in the environment.

[47] Existing EU legislation aimed at protection of workers against risks to their health (including Chemical Agents Directive 98/24/EC[48] and Carcinogens Directive 2004/37/EC[49]) currently do not impose binding minimum requirements for controlling risks to workers' health during the use phase or throughout the life cycle of trichloroethylene.

In 2023, the United States United States Environmental Protection Agency (EPA) determined that trichloroethylene presents a risk of injury to human health in various uses, including during manufacturing, processing, mixing, recycling, vapor degreasing, as a lubricant, adhesive, sealant, cleaning product, and spray.

[51][52] As of June 1, 2023, two U.S. states (Minnesota and New York) have acted on the EPA's findings and banned trichloroethylene in all cases but research and development.

[58] Many of the trichloroethylene uses that are continuing for longer than one year occur in highly industrialized settings with critical uses such as the cleaning of parts used in medical devices, aircraft & other transportation, security and defense systems and the manufacture of battery separators & refrigerants.

[58] Recent research has focused on the in-place remediation of trichloroethylene in soil and groundwater using potassium permanganate instead of removal for off-site treatment and disposal.

[61] Groundwater and drinking water contamination from industrial discharge including trichloroethylene is a major concern for human health and has precipitated numerous incidents and lawsuits in the United States.

The 1995 non-fiction book A Civil Action was written about a lawsuit (Anderson v. Cryovac) against following the increase in cancer cases after trichloroethylene pollution incidents and it was adapted to cinema in 1998.