Stress–strain curve

The stress and strain can be normal, shear, or a mixture, and can also be uniaxial, biaxial, or multiaxial, and can even change with time.

A schematic diagram for the stress–strain curve of low carbon steel at room temperature is shown in figure 1.

The stress is proportional to the strain, that is, obeys the general Hooke's law, and the slope is Young's modulus.

The stress of the flat region is defined as the lower yield point (LYP) and results from the formation and propagation of Lüders bands.

As the strain accumulates, work strengthening gets reinforced, until the stress reaches the ultimate tensile strength.

Beyond tensile strength, a necking forms where the local cross-sectional area becomes significantly smaller than the average.

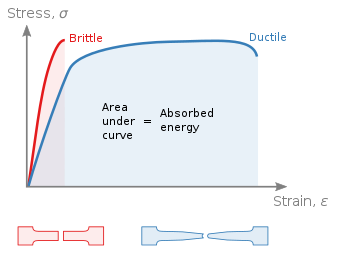

[1]: 51 Ductile materials, including structural steel and many other metals, are characterized by their ability to yield at normal temperatures.

[1]: 58 For example, low-carbon steel generally exhibits a very linear stress–strain relationship up to a well-defined yield point.

Permanent deformation occurs once dislocations are forced to move past pinning points.

The resulting slip bands appear at the lower yield point and propagate along the gauge length, at constant stress, until the Lüders strain is reached, and deformation becomes uniform.

During this stage, the cross-sectional area decreases uniformly along the gauge length, due to the incompressibility of plastic flow (not because of the Poisson effect, which is an elastic phenomenon).

Then a process of necking begins, which ends in a 'cup and cone' fracture characteristic of ductile materials.

where Brittle materials, which include cast iron, glass, and stone, are characterized by the fact that rupture occurs without any noticeable prior change in the rate of elongation,[1]: 59 sometimes they fracture before yielding.

Brittle materials such as concrete or carbon fiber do not have a well-defined yield point, and do not strain-harden.

One of the characteristics of a brittle failure is that the two broken parts can be reassembled to produce the same shape as the original component as there will not be a neck formation like in the case of ductile materials.