Turbojet

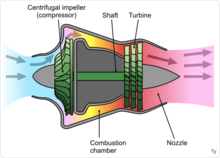

The compressed air from the compressor is heated by burning fuel in the combustion chamber and then allowed to expand through the turbine.

The turbine exhaust is then expanded in the propelling nozzle where it is accelerated to high speed to provide thrust.

Turbojet engines have been used in isolated cases to power vehicles other than aircraft, typically for attempts on land speed records.

Turbojets were used on Concorde and the longer-range versions of the Tu-144 which were required to spend a long period travelling supersonically.

Turbojets are still common in medium range cruise missiles, due to their high exhaust speed, small frontal area, and relative simplicity.

The first patent for using a gas turbine to power an aircraft was filed in 1921 by Frenchman Maxime Guillaume.

[2] His engine was to be an axial-flow turbojet, but was never constructed, as it would have required considerable advances over the state of the art in compressors.

[3] In 1928, British RAF College Cranwell cadet[4] Frank Whittle formally submitted his ideas for a turbojet to his superiors.

Practical axial compressors were made possible by ideas from A.A. Griffith in a seminal paper in 1926 ("An Aerodynamic Theory of Turbine Design").

Whittle's team experienced near-panic during the first start attempts when the engine accelerated out of control to a relatively high speed despite the fuel supply being cut off.

[7][8] On 27 August 1939 the Heinkel He 178, powered by von Ohain's design, became the world's first aircraft to fly using the thrust from a turbojet engine.

It was designed to test the Whittle jet engine in flight, and led to the development of the Gloster Meteor.

[11][12][13] Air is drawn into the rotating compressor via the intake and is compressed to a higher pressure before entering the combustion chamber.

The turbine exit gases still contain considerable energy that is converted in the propelling nozzle to a high speed jet.

However, joint studies by Rolls-Royce and Snecma for a second generation SST engine using the 593 core were done more than three years before Concorde entered service.

The increase in reliability that came with the turbojet enabled three- and two-engine designs, and more direct long-distance flights.

[17] High-temperature alloys were a reverse salient, a key technology that dragged progress on jet engines.

Non-UK jet engines built in the 1930s and 1940s had to be overhauled every 10 or 20 hours due to creep failure and other types of damage to blades.

[20] Early German turbojets had severe limitations on the amount of running they could do due to the lack of suitable high temperature materials for the turbines.

[21] General Electric in the United States was in a good position to enter the jet engine business due to its experience with the high-temperature materials used in their turbosuperchargers during World War II.

[22] Water injection was a common method used to increase thrust, usually during takeoff, in early turbojets that were thrust-limited by their allowable turbine entry temperature.

The water increased thrust at the temperature limit, but prevented complete combustion, often leaving a very visible smoke trail.

On early engines, the turbine temperature limit had to be monitored, and avoided, by the pilot, typically during starting and at maximum thrust settings.

A nose bullet is a component of a turbojet used to divert air into the intake, in front of the accessory drive and to house the starter motor.

The turbine rotates the compressor at high speed, adding energy to the airflow while squeezing (compressing) it into a smaller space.

Supplying bleed air to the aircraft decreases the efficiency of the engine because it has been compressed, but then does not contribute to producing thrust.

In a turbojet, the air and fuel mixture burn in the combustor and pass through to the turbine in a continuous flowing process with no pressure build-up.

Less than 25% of the air is typically used for combustion, as an overall lean mixture is required to keep within the turbine temperature limits.

Liquid injection was tested on the Power Jets W.1 in 1941 initially using ammonia before changing to water and then water-methanol.

At normal subsonic speeds this reduces the propulsive efficiency, giving an overall loss, as reflected by the higher fuel consumption, or SFC.