Vertical-axis wind turbine

This arrangement allows the generator and gearbox to be located close to the ground, facilitating service and repair.

Major drawbacks for the early designs (Savonius, Darrieus and giromill) included the significant torque ripple during each revolution and the large bending moments on the blades.

[3] Savonius vertical-axis wind turbines (VAWT) are not widespread, but their simplicity and better performance in disturbed flow-fields, compared to small horizontal-axis wind turbines (HAWT) make them a good alternative for distributed generation devices in an urban environment.

[5][6] Recent advancements in small wind turbine technology include the integration of Internet of Things (IoT) systems to enhance performance and efficiency.

IoT-enabled wind turbines can collect and analyze real-time operational data, allowing for predictive maintenance, remote monitoring, and integration with smart grids.

These technologies help optimize energy production, reduce downtime, and improve overall system reliability.

These turbines typically have three slim rotor blades driven by lift forces, allowing them to achieve high speeds.

In practice, you may come across a range of variations and combinations, with developers frequently demonstrating their creativity in crafting diverse forms of vertical wind turbines.

The original design included a number of curved aerofoil blades with the tips attached on a rotating shaft.

However, there are also designs that use straight vertical airfoils, referred to as H-rotor or Giromill Darrieus wind turbines.

Revolving wing wind turbines or rotating wing wind turbines are a new category of lift-type VAWTs which use 1 vertically standing, non-helical airfoil to generate 360-degree rotation around a vertical shaft that runs through the center of the airfoil.

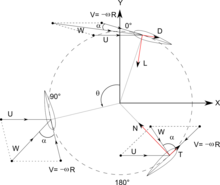

[16] VAWTs often suffer from dynamic stall of the blades as the angle of attack varies rapidly.

[17][18][19] The blades of a VAWT are fatigue-prone due to the wide variation in applied forces during each rotation.

Other than the drag-types, VAWTs have proven less reliable than HAWTs,[20] although modern designs have overcome many early issues.

Other optimizations included array angle, rotation direction, turbine spacing, and number of rotors.

[23] In 2022 Norway's World Wide Wind introduced floating VAWTs with two sets of counter-rotating blades.

VAWTs place most of the heavy components at the bottom of the tower, reducing the need for counterbalance.

[24] The Windspire, a small VAWT intended for individual (home or office) use was developed in the early 2000s by US company Mariah Power.

[25] Arborwind, an Ann Arbor, Michigan, based company, produces a patented small VAWT which has been installed at several US locations as of 2013.

[26] In 2011, Sandia National Laboratories wind-energy researchers began a five-year study of applying VAWT design technology to offshore wind farms.

[27] The researchers stated: "The economics of offshore windpower are different from land-based turbines, due to installation and operational challenges.

A 24-unit VAWT demonstration plot was installed in southern California in the early 2010s by Caltech aeronautical professor John Dabiri.

[28] Dulas, Anglesey, received permission in March 2014 to install a prototype VAWT on the breakwater at Port Talbot waterside.

The turbine is a new design, supplied by Wales-based C-FEC (Swansea),[29] and will be operated for a two-year trial.

[31] Architect Michael Reynolds (known for his Earthship house designs) developed a 4th-generation VAWT named Dynasphere.