Virginia-class submarine

The class is designed for a broad spectrum of open-ocean and littoral missions, including anti-submarine warfare and intelligence gathering operations.

To reduce costs, the Virginia-class submarines use many "commercial off-the-shelf" (COTS) components, especially in their computers and data networks.

[26] In hearings before both House of Representatives and Senate committees, the Congressional Research Service (CRS) and expert witnesses testified that the annual procurement rate of only one Virginia-class boat—rising to two in 2012—would result in excessive unit production costs, yet an insufficient complement of attack submarines.

[29][30] The Virginia class is built through an industrial arrangement designed to maintain both GD Electric Boat and Newport News Shipbuilding, the only two U.S. shipyards capable of building nuclear-powered submarines.

O'Rourke wrote in 2004 that, "Compared to a one-yard strategy, approaches involving two yards may be more expensive but offer potential offsetting benefits.

"[32] Among the claims of "offsetting benefits" that O'Rourke attributes to supporters of a two-facility construction arrangement is that it "would permit the United States to continue building submarines at one yard even if the other yard is rendered incapable of building submarines permanently or for a sustained period of time by a catastrophic event of some kind", including an enemy attack.

In December 2010, the United States Congress passed a defense authorization bill that expanded production to two subs per year.

[40] In September 2010, it was found that urethane tiles, applied to the hull to damp internal sound and absorb rather than reflect sonar pulses, were falling off while the subs were at sea.

[3] On 14 September 2023, at a Senate confirmation hearing, Admiral Lisa Franchetti said that the US Navy would have to work with builders to raise the rate of production from 1.2/year to 2.2/year to meet the AUKUS target.

[26] Because of the low rate of Virginia production, the Navy entered into a program with DARPA to overcome technology barriers to lower the cost of attack submarines so that more could be built, to maintain the size of the fleet.

[52] The current photonics masts have a visual appearance so different from ordinary periscopes that when the submarine is detected, it can be distinctly identified as a Virginia-class vessel.

[52] In the future, a non-rotational Affordable Modular Panoramic Photonics Mast may be fitted, enabling the submarine to obtain a simultaneous 360° view of the sea surface.

[62][63] In contrast to a traditional bladed propeller, the Virginia class uses pump-jet propulsors by BAE Systems,[64] originally developed for the Royal Navy's Swiftsure-class submarines.

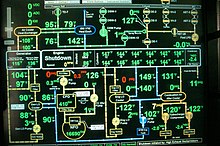

Sonar arrays aboard Virginia-class submarines have an "Open System Architecture" (OSA) which enables rapid insertion of new hardware and software as they become available.

[78] The Block V submarines built from 2019 onward will have an additional Virginia Payload Module (VPM) mid-body section, increasing their overall length.

The VPM will add four more VPTs of the same diameter and greater height, located on the centerline, carrying up to seven Tomahawk missiles apiece, that would replace some of the capabilities lost when the SSGN conversion Ohio-class submarines are retired from the fleet.

[32][79] Initially eight payload tubes/silos were planned[79] but this was later rejected in favor of four tubes installed in a 70-foot (21 m) long module between the operations compartment and the propulsion spaces.

[86] In February 2017 General Dynamics was awarded $126 million for long lead time construction of Block V submarines equipped with VPM.

[87] The VPM was designed by General Dynamics Electric Boat;[88] however, manufacturing is undertaken by BWX Technologies and BAE Systems.

[clarification needed][122] South Dakota (SSN-790) will be equipped with a new propulsor,[123] possibly the Hybrid Multi-Material Rotor (HMMR),[124][125] developed by Defense Advanced Research Projects Agency (DARPA).

[127] The most costly shipbuilding contract in history, worth $17.6 billion, was awarded on 28 April 2014 to General Dynamics Electric Boat.

The main improvement over the Block III is the reduction of major maintenance periods from four to three, increasing each boat's total lifetime deployments by one.

[131] Block V has 10 boats and may incorporate the Virginia Payload Module (VPM), which would give guided-missile capability when the SSGNs are retired from service.

[4] On 22 March 2021, the U.S. Navy added the 10th boat of the Block V series of the Virginia-class attack submarine, issuing a $2.4 billion adjustment on the December 2019 contract.

[202][203] However, other sources believe that production will end with Block V.[204] In addition, data provided in CBO reports tends to vary considerably compared to earlier editions.

[205] General Dynamics Electric Boat, a business unit of General Dynamics, announced on 5 August 2024 it has been awarded a $1.3 billion undefinitized contract modification allowing Electric Boat to purchase long lead time materials for Virginia Class Block VI submarines.

[206] During the Naval Submarine League's annual symposium on 13 November 2024 plans for extending Virginia class to Block VIII - due to SSN(X) delays - were voiced.

An initial small team has been formed to consult with industry and identify the threat environment and technologies the submarine will need to operate against in the 2050-plus timeframe.

[213][214] The Royal Australian Navy (RAN) would acquire at least eight nuclear-powered submarines armed with conventional weapons with basic design and key technologies decided by an 18-month research project.

[218][219][220] The SSN-AUKUS class "will have a high degree of commonality" with the Virginia-class, including "sharing elements of the propulsion plant, combat system and weapons".