Watermill

The former type can be further subdivided, depending on where the water hits the wheel paddles, into undershot, overshot, breastshot and pitchback (backshot or reverse shot) waterwheel mills.

The former type can be further divided, depending on where the water hits the wheel paddles, into undershot, overshot, breastshot and reverse shot waterwheel mills.

[2] The earliest evidence of a water-driven wheel appears in the technical treatises Pneumatica and Parasceuastica of the Greek engineer Philo of Byzantium (ca.

Lewis has shown that those portions of Philo of Byzantium's mechanical treatise which describe water wheels and which have been previously regarded as later Arabic interpolations, actually date back to the Greek 3rd century BC original.

[4] The sakia gear is, already fully developed, for the first time attested in a 2nd-century BC Hellenistic wall painting in Ptolemaic Egypt.

[6] The Greek geographer Strabo reports in his Geography a water-powered grain-mill to have existed near the palace of king Mithradates VI Eupator at Cabira, Asia Minor, before 71 BC.

[7] The Roman engineer Vitruvius has the first technical description of a watermill, dated to 40/10 BC; the device is fitted with an undershot wheel and power is transmitted via a gearing mechanism.

For Demeter has imposed the labours of your hands on the nymphs, who leaping down upon the topmost part of the wheel, rotate its axle; with encircling cogs,[12] it turns the hollow weight of the Nisyrian millstones.

If we learn to feast toil-free on the fruits of the earth, we taste again the golden age.The Roman encyclopedist Pliny mentions in his Naturalis Historia of around 70 AD water-powered trip hammers operating in the greater part of Italy.

[14] The 2nd century AD multiple mill complex of Barbegal in southern France has been described as "the greatest known concentration of mechanical power in the ancient world".

The capacity of the mills has been estimated at 4.5 tons of flour per day, sufficient to supply enough bread for the 12,500 inhabitants occupying the town of Arelate at that time.

A breastshot wheel mill dating to the late 2nd century AD was excavated at Les Martres-de-Veyre, France.

[17] The 3rd century AD Hierapolis water-powered stone sawmill is the earliest known machine to incorporate the mechanism of a crank and connecting rod.

[19] Literary references to water-powered marble saws in what is now Germany can be found in Ausonius 4th century AD poem Mosella.

They also seem to be indicated about the same time by the Christian saint Gregory of Nyssa from Anatolia, demonstrating a diversified use of water-power in many parts of the Roman Empire.

[20] The earliest turbine mill was found in Chemtou and Testour, Roman North Africa, dating to the late 3rd or early 4th century AD.

[22] Mills were commonly used for grinding grain into flour (attested by Pliny the Elder), but industrial uses as fulling and sawing marble were also applied.

Greek style mills are the older and simpler of the two designs, but only operate well with high water velocities and with small diameter millstones.

Although to date only a few dozen Roman mills are archaeologically traced, the widespread use of aqueducts in the period suggests that many remain to be discovered.

The surviving evidence for watermills sharply increases with the emergence of documentary genres such as monastic charters, Christian hagiography and Germanic legal codes.

[29] Later research estimates a less conservative number of 6,082 that should be considered a minimum as the northern reaches of England were never properly recorded.

[37][38] In a 2005 survey the scholar Adam Lucas identified the following first appearances of various industrial mill types in Western Europe.

The waterwheel was found in China from 30 AD onwards, when it was used to power trip hammers,[41] the bellows in smelting iron,[42][43] and in one case, to mechanically rotate an armillary sphere for astronomical observation (see Zhang Heng).

By the 11th century, every province throughout the Islamic world had these industrial watermills in operation, from al-Andalus and North Africa to the Middle East and Central Asia.

This technique was employed along the Tigris and Euphrates rivers in 10th-century Iraq, where large ship mills made of teak and iron could produce 10 tons of flour from corn every day for the granary in Baghdad.

Most watermills in Britain and the United States of America had a vertical waterwheel, one of four kinds: undershot, breast-shot, overshot and pitchback wheels.

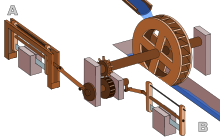

The usual arrangement in British and American corn mills has been for the waterwheel to turn a horizontal shaft on which is also mounted a large pit wheel.

The earliest illustration of a single waterwheel driving more than one set of stones was drawn by Henry Beighton in 1723 and published in 1744 by J. T.

[citation needed] The last two examples in the United Kingdom which are restored to working conditions can be visited at Eling, Hampshire and at Woodbridge, Suffolk.

According to Cedrenus (Historiarum compendium), a certain Metrodoros who went to India in c. AD 325 "constructed water-mills and baths, unknown among them [the Brahmans] till then".