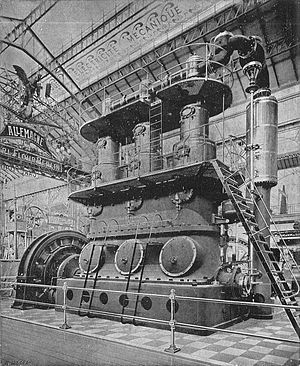

Willans engine

This vertical arrangement of the steeple compound gives a compact floor layout for an engine of such power.

[5] The engines were developed by Peter W. Willans and Mark Robinson at Thames Ditton, primarily for the increasing market in electrical generation.

The Willans engine, its low inertia and accurate speed control made it highly suitable for mill work.

[12] The Willans engine was single-acting; steam pressure was only applied to the upper surface of the pistons.

This was a common feature of high-speed engines at this time, in a measure to reduce knocking and increased wear, thus permitting higher operating speeds.

In the conventional double-acting engine, residual steam was trapped in the exhausting cylinder after the valve closed and compressed.

Unusually the valve worked within the hollow piston rod or trunk, rather than in the cylinder block or valvechest.

Each piston had two parallel connecting rods, working on separated crankpin journals between the same crank webs.

[15] Inlet steam was supplied to the top of the piston rod trunk through distinctive domed caps.

If the engine was intended for a fixed cutoff, the inlet steam was controlled solely by the valve and trunk.

Their invention in 1890 of the oil pump and forced lubrication system solved the problem of the bearing rattling under a reversing load.

The Carel engine, built by SA des Moteurs á Grand Vitesse.

He left Willans in January 1892 and in 1893 he approached James Paxman with his own design of a high-speed single-acting engine.

[13] Piston valves behind the cylinders were worked by a form of radial valvegear, driven by the connecting rod.

By slightly offsetting the crankshaft and piston axis, the crosshead forces remained towards the rear of the engine, throughout the operating cycle.

[22] Like the single-acting principle itself, this constant direction of forces helped to reduce vibration and wear.

A 1901, 140 bhp three cylinder generating set was retired in 1957 from the Maples furniture shop in London and placed on display at the original Willans factory in Rugby.